Introduction

Boilers play a crucial role in various industries, facilitating energy conversion and improving production efficiency. ZOZEN, a renowned manufacturer with rich experience and expertise, stands out in the boiler in industry, continuously delivering innovative and reliable solutions for industrial boilers.

Part 1: Importance and Applications of Boiler in Industry

Boiler in industry is indispensable that require heating, power generation, or steam production. They are extensively used in sectors such as manufacturing, chemical processing, food processing, and more. Boilers provide essential thermal energy for diverse industrial processes, ensuring smooth operations, high productivity, and cost savings.

As a leading manufacturer, ZOZEN recognizes the significance of boiler in industry and offers tailored solutions to meet the specific requirements of different sectors. With their expertise, ZOZEN consistently delivers advanced boiler technologies, contributing to the overall growth and efficiency of industrial operations.

Part 2: ZOZEN’s Position and History of Boiler in Industry

ZOZEN has established a strong position of boiler in industry through its commitment to quality, innovation, and customer satisfaction. With a rich history spanning several decades, the company has accumulated vast experience and technical expertise.

Having witnessed the evolution of boiler technology, ZOZEN has continuously adapted and advanced its manufacturing processes to meet industry demands. By incorporating cutting-edge research and development, ZOZEN has successfully developed a wide range of boilers that cater to diverse industrial applications.

Part 3: ZOZEN’s Best-Selling Boiler Products

ZOZEN offers a comprehensive portfolio of boiler products, catering to different fuel types.

For oil and gas fuels, the WNS series, SZS series, YQW series, and YQL series boilers are available.

The WNS series steam boiler in industry is a three-pass wet-back oil/gas-fired boiler with a thermal capacity of 1-20 t/h and a working pressure of 0.7-2 MPa. Equipped with an advanced control system, it enables unmanned operation.

The SZS series industrial steam boiler features a double-drum, horizontal, and D-type arrangement, with a thermal capacity of 2-110 t/h and a working pressure of 1.25-5.3 MPa. Its membrane water-cooled wall and large furnace design enhance heat transfer efficiency.

For biomass and coal fuels, ZOZEN offers the SZL series, SHX series, DZL series, DHL series, DHX series, and YLW series boilers.

The SZL series industrial steam boiler is a horizontal, double-drum, chain grate, and water tube boiler, with a thermal capacity of 6-35 t/h and a working pressure of 1-2.5 MPa. Its furnace adopts a densely arranged water-cooled wall tube structure, providing a large radiation heating area.

The SHX series industrial steam boiler is a circulating fluidized bed boiler, suitable for a thermal capacity of 10-75 t/h and a working pressure of 1.25-2.45 MPa. Its high fuel adaptability and combustion efficiency make it ideal for low-calorific-value inferior coal.

ZOZEN also offers the DZL series industrial steam boiler, a horizontal, three-pass, water, and fire tube chain grate boiler, with a thermal capacity of 2-10 t/h and a working pressure of 1-2.5 MPa. The DZL series boiler features a lightweight chain grate and is delivered in a quick-assemble form.

The DHL series industrial steam boiler is a corner tube boiler, with a thermal capacity of 20-75 t/h and a working pressure of 1.25-5.4 MPa. It utilizes a beam-type chain grate and a membrane water-cooled wall structure to ensure complete fuel combustion.

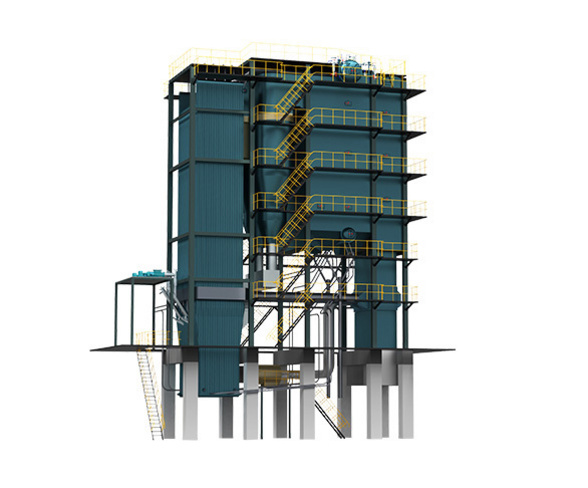

The DHX series industrial steam boiler is a circulating fluidized bed boiler, offering a thermal capacity of 35-75 t/h and a working pressure of 1.25-5.3 MPa. The boiler produces ash with good activity, facilitating comprehensive utilization without secondary ash pollution.

Lastly, the YLW series is a horizontal coal and biomass-fired thermal oil boiler, with a thermal capacity of 1400-29000 kW and a working pressure of 0.8-1.0 MPa. Equipped with an advanced control system, it ensures precise control of oil temperature and pressure.

In addition to these products, ZOZEN has independently developed a biomass boiler with proprietary intellectual property—the DZL series horizontal non-clogging biomass steam boiler. With a thermal capacity of 15-40 t/h and a working pressure of 1.25-2.5 MPa, the boiler features soot blowing devices at the rear and blowholes at the top, allowing for ash removal without shutting down the boiler.

ZOZEN DZL Series Horizontal Non-clogging Biomass Steam Boiler in Industry

Part 4: ZOZEN’s Technological Innovation in the Boiler in Industry

ZOZEN remains at the forefront of technological innovation in the industrial boiler field. The company continuously invests in research and development, focusing on enhancing boiler performance, efficiency, and safety.

One of the notable innovations by ZOZEN is its intelligent control system, which incorporates advanced automation and monitoring capabilities. This system allows for precise control of various boiler parameters, optimizing fuel consumption, and ensuring stable operation. With intelligent control, ZOZEN’s boilers can achieve unmanned and remote operation, minimizing human intervention and improving overall efficiency.

ZOZEN also emphasizes high-efficiency combustion technologies in its boiler designs. By incorporating advanced combustion mechanisms, such as staged combustion and low-NOx burners, ZOZEN boilers achieve cleaner and more efficient fuel combustion. This results in reduced emissions, improved energy utilization, and compliance with stringent environmental regulations.

ZOZEN’s technical innovations extend beyond control systems and combustion technologies. The company continually explores advancements in heat transfer, materials, and structural design to enhance overall boiler performance. By optimizing heat exchange surfaces, adopting heat recovery systems, and utilizing advanced materials, ZOZEN ensures maximum energy transfer and minimal heat loss.

These technological innovations by ZOZEN contribute to increased boiler efficiency, reduced operating costs, and improved environmental sustainability. With customizable solutions and a commitment to continuous improvement, ZOZEN meets the diverse needs of various industries, enabling them to achieve their production goals while minimizing resource consumption.

Conclusion

In the realm of boiler in industry, ZOZEN stands as a reliable and innovative manufacturer. With a wide range of high-quality products tailored to different fuel types, the company provides comprehensive solutions for industrial boiler applications. ZOZEN’s commitment to technological innovation, including intelligent control systems and high-efficiency combustion technologies, ensures enhanced performance, efficiency, and environmental sustainability. As industries continue to evolve, ZOZEN remains dedicated to delivering reliable and advanced boiler solutions, driving the progress of the industrial sector.