Case Introduction

BaoTi Huashen Titanium Industry Co., Ltd. is a high-tech enterprise integrating the research, production, and sales of titanium materials. With its strong technical strength and extensive production experience, the company has become one of the leading enterprises in China’s titanium industry.

The production of titanium and titanium alloys requires precise thermal energy control, especially in high-temperature smelting and metal processing stages. To ensure product quality and production efficiency, the titanium industry typically relies on high-temperature heat sources. Thermal oil boilers, as an efficient heat energy equipment, are widely used in various stages of titanium production such as heating and temperature control, providing stable and reliable heat sources.

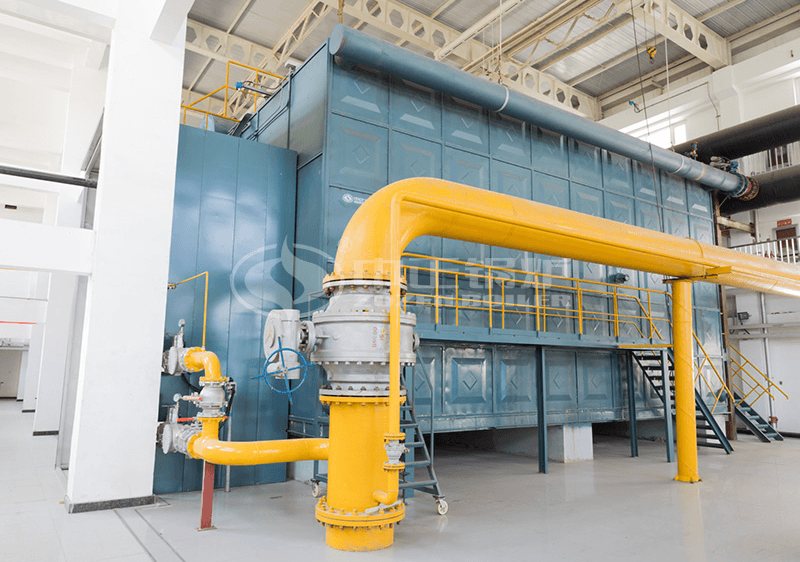

In this context, Bao Titanium Huashen Titanium Industry Co., Ltd. urgently needed a thermal oil boiler solution that not only meets high-temperature energy requirements but also features high energy efficiency. Leveraging its technical advantages in the thermal oil boiler field, ZOZEN Boiler customized a suitable thermal energy system for Bao Titanium Huashen.

The 3.6 million kcal gas-fired thermal oil boiler provided by ZOZEN Boiler for Bao Titanium Huashen takes into full account the high-temperature heat source needs of titanium production. With a thermal efficiency of over 94%, this boiler significantly reduces energy consumption while providing the same amount of heat. Compared to traditional boilers, the gas-fired thermal oil boiler not only improves energy utilization but also effectively reduces production costs.

In addition, ZOZEN Boiler’s thermal oil boilers excel in fuel adaptability, allowing them to flexibly accommodate different fuel types based on Bao Titanium Huashen’s production needs. This advantage provides the company with greater flexibility in energy procurement and better cost control, thus improving overall production efficiency and economic benefits.

ZOZEN Boiler’s thermal oil boilers not only meet industry environmental standards, boasting low emissions and significant energy-saving features, but also include intelligent control systems that enable precise monitoring and optimization of boiler operation. This provides Bao Titanium Huashen with a more efficient and environmentally friendly thermal energy solution.

By adopting ZOZEN’s gas-fired thermal oil boiler, Bao Titanium Huashen has successfully optimized energy consumption while ensuring product quality and production efficiency, resulting in significant energy cost savings for the company. Additionally, the high efficiency of the thermal oil boiler has reduced maintenance frequency and failure rates, further enhancing overall production stability and reliability.

The demand for high-temperature heat sources in the production process of Bao Titanium Huashen Titanium Industry Co., Ltd. is indispensable. ZOZEN Boiler, with its advanced thermal oil boiler technology, has provided the company with an efficient, economical, and environmentally friendly thermal energy solution. Through this solution, Bao Titanium Huashen has not only improved production efficiency and reduced energy consumption but has also achieved significant environmental and economic returns. In the future, Bao Titanium Huashen will continue to develop steadily with the support of ZOZEN Boiler, maintaining its leadership position in the industry.

Customer Feedback

Choosing to cooperate with ZOZEN Boiler and purchasing their thermal oil boiler was an important decision for our company to improve production efficiency and reduce energy costs. The 3.6 million kcal gas-fired thermal oil boiler provided by ZOZEN Boiler not only offers excellent thermal efficiency but also excels in fuel adaptability and environmental performance. Since the equipment was put into operation, the boiler has been running steadily with a very low failure rate, and the temperature control during the production process has become more precise, significantly improving product quality and production efficiency.— BaoTi Huashen Titanium Industry Co., Ltd.