Case Introduction

A cottonseed oil factory in Tanzania is in search of a boiler solution that can meet production needs while reducing environmental impact. Based on the specific requirements of the customer, ZOZEN Boiler recommended the DZL series third-generation biomass steam boiler and successfully gained the trust of the customer.

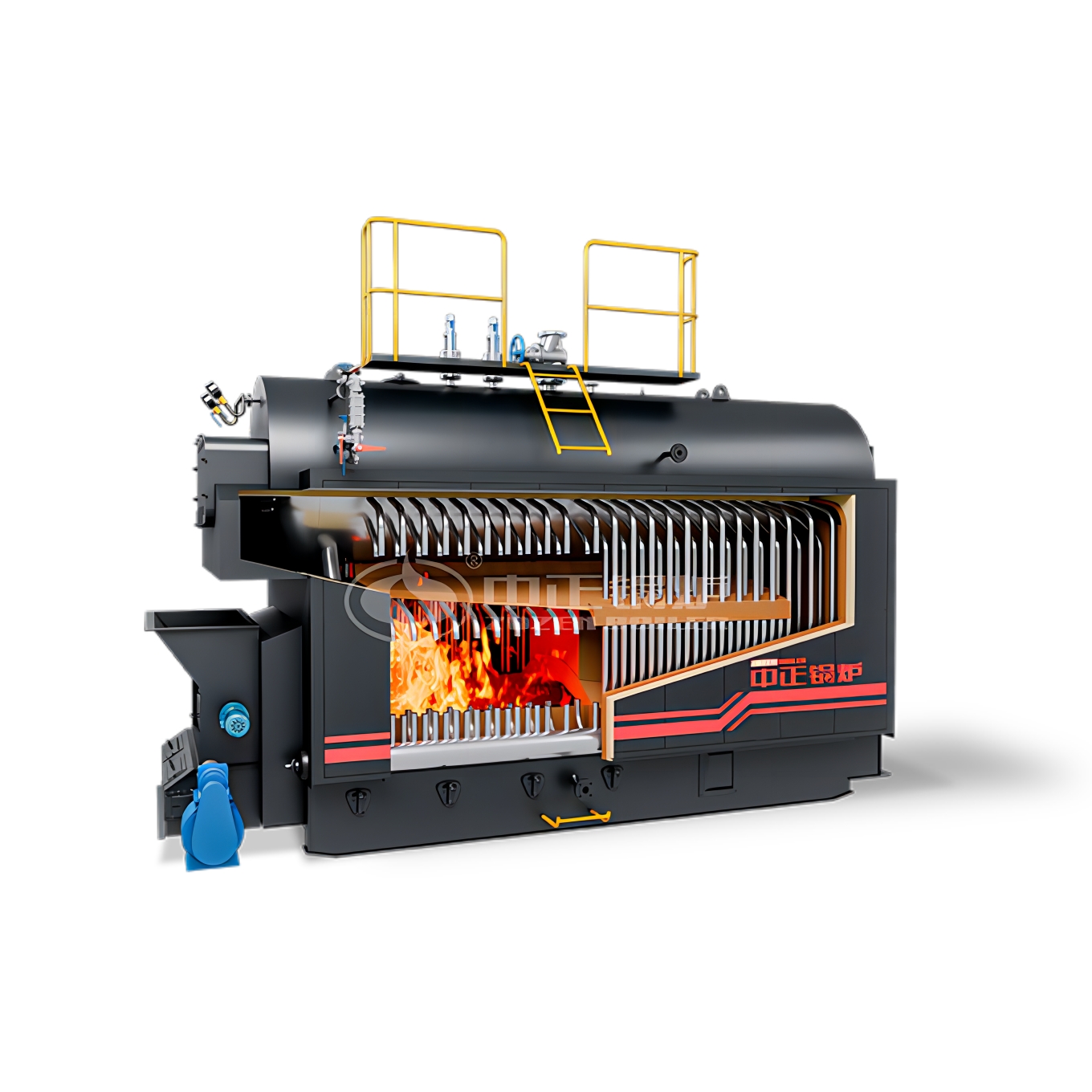

Innovative Design: The standout feature of the DZL series boiler lies in its chain grate and independent air chamber design. This design ensures thorough combustion of fuels such as biomass pellets, rice husks, wood chips, corn cobs, and sawdust, achieving over 87.5% thermal efficiency.

Efficient Heat Conversion: Water-cooled walls surround the front part of the boiler body, while convective tube bundles are arranged between the upper and lower boiler drums at the rear. After the high-temperature flue gas passes through these heat exchange surfaces, it is discharged through the economizer and dust collector, optimizing heat conversion and utilization.

Environmental Benefits: The DZL series third-generation biomass steam boiler, as an efficient and environmentally friendly energy solution, not only meets production needs but also effectively reduces production costs, helping customers achieve greener production goals.

Customer Feedback

We are deeply impressed by the products and services of ZOZEN Boiler. The high efficiency and environmentally friendly design of the DZL series boiler perfectly align with our needs. Since installation, the boiler has been running smoothly, significantly reducing our production costs and minimizing environmental impact. We appreciate the professional support and quality equipment provided by ZOZEN Boiler, making our production process more efficient and sustainable. — Triwin Agricultural Resources (Tanzania) Ltd