Case Introduction

Anhui Xingzhou Pharmaceutical Co., Ltd., as a high-tech enterprise specializing in gluconolactone and its series of products, has strict requirements for steam usage in its production process. In pharmaceutical manufacturing, steam boilers play a crucial role. They are not only used for sterilization and disinfection in the production process but also extensively applied in raw material extraction, preparation of formulations, and other stages. Therefore, the pharmaceutical industry has stringent requirements for the stability, safety, and environmental performance of steam boilers.

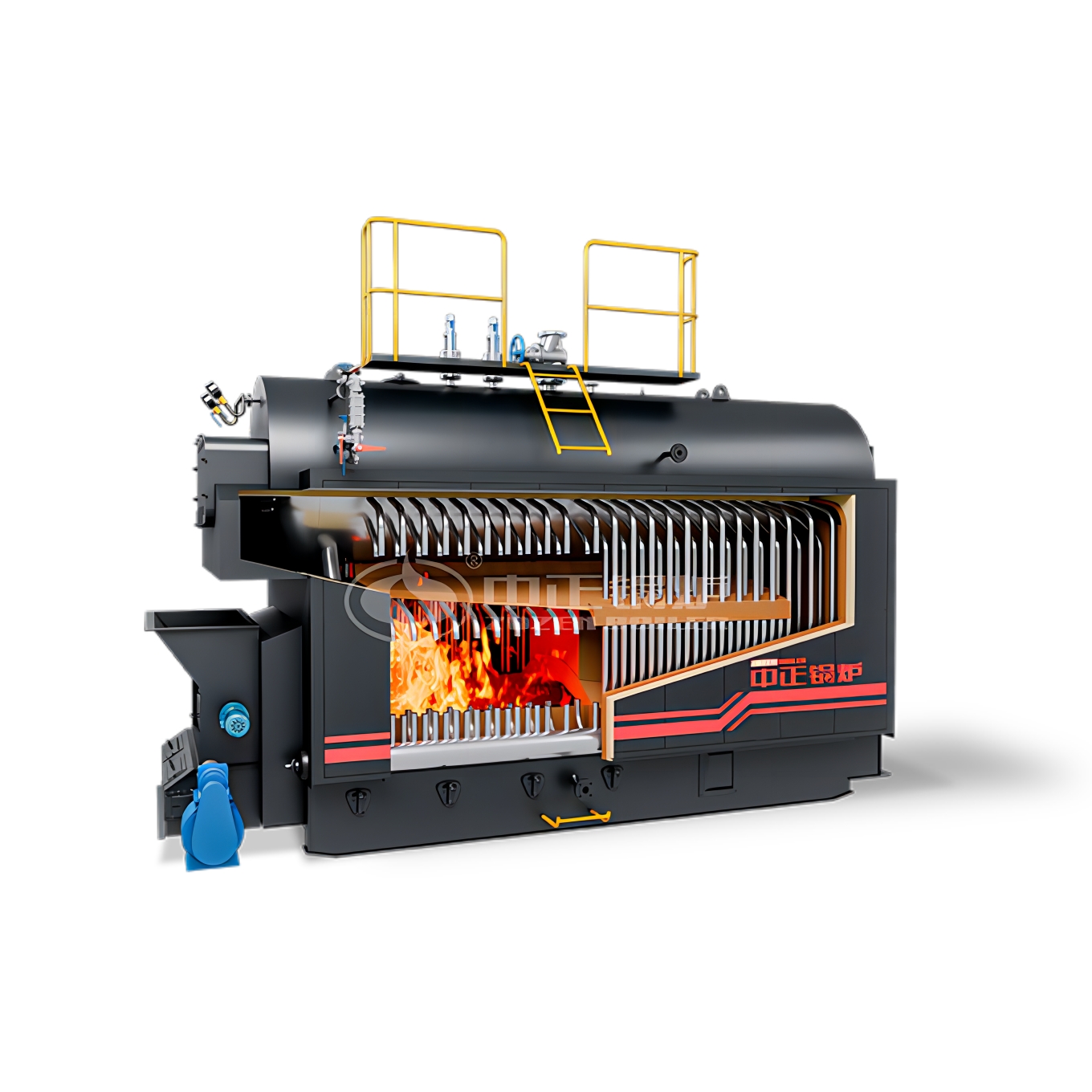

ZOZEN Boiler provided the DZL series non-clogging biomass steam boiler, which can use various fuels such as biomass pellets, rice husks, and wood chips, effectively reducing fuel costs while responding to the national call for energy conservation and emission reduction. Moreover, it adopts a densely arranged water-cooled wall tube structure, paired with a customized boiler system, achieving a thermal efficiency of over 87.5%, significantly reducing energy consumption.

Anhui Xingzhou Pharmaceutical Co., Ltd., as a high-tech enterprise specializing in gluconolactone and its series of products, has extremely strict requirements for steam in its production process. Steam plays a central role in pharmaceutical manufacturing, running through various stages such as sterilization, disinfection, raw material extraction, and formulation preparation. Steam is not only one of the key factors ensuring production efficiency and product quality but also directly affects the safety and compliance of pharmaceutical processes. Therefore, the pharmaceutical industry has stricter standards for the stability, safety, and environmental performance of steam boilers than other industries.

In this context, ZOZEN Boiler provided Anhui Xingzhou Pharmaceutical Co., Ltd. with advanced DZL series non-clogging biomass steam boilers. These boilers, with their excellent performance and diverse fuel options, perfectly meet the pharmaceutical industry’s high standards for steam supply. The DZL series biomass steam boiler can use various renewable fuels such as biomass pellets, rice husks, and wood chips, significantly reducing fuel costs while helping the company achieve sustainable development goals alongside stable production. By adopting these green fuels, the boiler responds to the national policy of energy conservation and emission reduction, promoting environmentally friendly production.

In terms of technical design, ZOZEN’s DZL series boilers adopt a densely arranged water-cooled wall tube structure, which effectively improves the boiler’s heat exchange efficiency, ensuring maximum utilization of heat. Paired with a customized boiler system, the DZL series achieves a thermal efficiency of over 87.5%, significantly reducing energy consumption. This not only lowers operating costs but also minimizes environmental impact. Additionally, the automatic ash cleaning system integrated into the boiler solves the problem of ash accumulation common in traditional boilers, further enhancing the ease of maintenance and extending the equipment’s service life.

With its outstanding technological advantages and excellent product performance, ZOZEN’s DZL series biomass steam boiler provides stable thermal energy support for Anhui Xingzhou Pharmaceutical Co., Ltd., helping it maintain a leading edge in the industry while achieving both economic and environmental benefits.

Customer Feedback

Since introducing ZOZEN Boiler‘s DZL series non-clogging biomass steam boiler, our production efficiency has significantly improved. The boiler operates stably, providing a consistent supply of steam, and can use a variety of biomass fuels, which has greatly reduced our fuel costs. Additionally, the boiler’s environmental performance is outstanding, aligning with national energy-saving and emission reduction policies. ZOZEN’s technical support team is very professional, always ready to provide efficient service. Overall, we are extremely satisfied with this collaboration!— Anhui Xingzhou Pharmaceutical Co., Ltd.