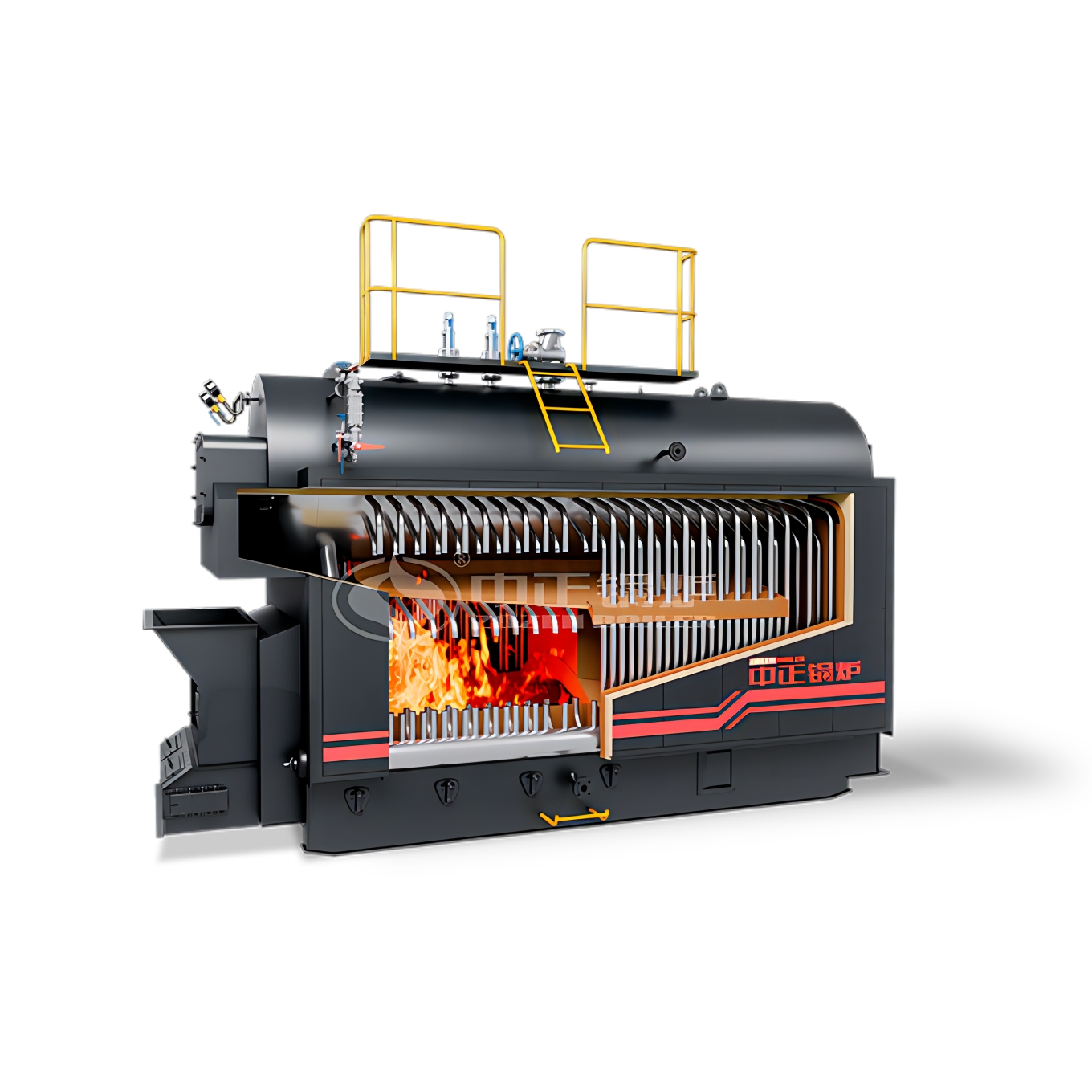

Industrial water tube boiler refers to an industrial boiler in which the combustion chamber and heating surface are set outside the boiler barrel, resulting in the flow of water and steam in the tube. The boiler has a complex structure. The steam system mainly includes a boiler tube, a collector, a water wall, a convection tube, a coal economizer, a superheater, etc. The combustion system mainly includes burner, furnace and flue, air preheater and so on. At present, the water tube boilers produced by Zhongzheng are more popular, such as SZS type gas boiler and DHL series biomass boiler. Compared with fire tube boilers, it has no large diameter boiler tube in structure, and the flexible bend water tube replaces the straight smoke tube, which not only saves metal, but also creates conditions for improving boiler capacity and steam parameters.

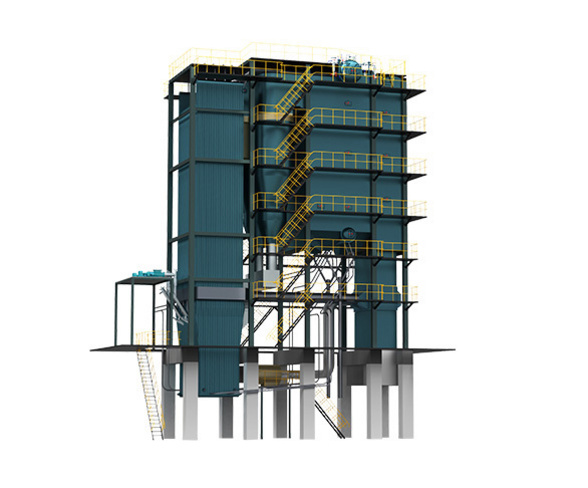

D type boiler is a frameless natural circulation double tube boiler tube boiler, with longitudinal arrangement of boiler tube, full-film water-wall structure and micro-positive pressure combustion. According to the product type can be divided into hot water, saturated steam and superheated steam boiler.

D type boilers use gas and liquid fuels and are suitable for steelmaking, coke oven gas and other waste gas and liquid fuels. They are equipped with the most modern combustion equipment and automatic control system to ensure the safest and most economical operation of boilers.

D type boilers range in use from chemical plants, steel mills, thermal companies, and various industrial companies to start-up boilers for power plants. It can also be used for heating, production processing and power generation. This boiler is suitable for indoor or outdoor operation.

The specific advantages of industrial water tube boiler are as follows:

- Water tube boiler furnace is placed outside the cylinder body, the volume of the furnace can be large or small, can meet the requirements of combustion and increase evaporation.

- Water tube boiler tube is generally not directly heated, to contain water vapor pipe placed in the furnace, flue as heating surface, heat transfer performance and safety performance has been significantly improved.

- Water pipe boiler water preheating, steam and steam superheating in the heating surface economizer, water cooling wall and convection tube, superheater.

- Water tube boiler water vapor system, combustion system and auxiliary system is more complex, but the water tube boiler single pressure component structure is relatively simple.

- Water tube boiler due to the water preheating, soda and steam overheat are completed in the pipe, pipe scaling is difficult to remove, so water tube boiler higher requirements for water quality, operation, management level is also higher requirements.

Zhongzheng boiler has been focusing on the production and manufacturing of gas-fired steam, gas-fired hot water and industrial water tube boiler for more than 30 years. The boiler models all meet the new national environmental protection standards, with ultra-low nitrogen emission, low operating and maintenance cost, and simple and convenient operation. Zhongzheng boiler is your trustworthy boiler manufacturer. Henan Yuanda Boiler, a designated enterprise authorized by the State boiler manufacturing License, has been engaged in the research, development, production and sales of environmental protection industrial boilers such as steam, hot water, vacuum and heat conduction oil for 63 years, and has been sold to more than 80 countries with perfect after-sales service. It is your trustworthy brand boiler manufacturer.