Rice mills play a crucial role in the processing of rice, and an essential component of these mills is the rice mill boiler machine. These industrial boilers are responsible for providing the necessary steam required for various stages of rice processing. In this article, we will explore the significance of rice mill boiler machines and discuss how to select the appropriate one for your needs.

Part 1: Choosing the Right Rice Mill Boiler Machine

Rice milling is a complex process that transforms raw rice into the polished grains we consume. In this process, rice mill boiler machines play a vital role by providing the steam required for different operations. Firstly, the boiler generates steam to soak and cook the paddy grains, facilitating the removal of the outer husk. This process, known as parboiling, enhances the nutritional value of rice. Additionally, the steam produced by the boiler is utilized for drying the rice, resulting in a longer shelf life and improved quality.

Selecting the appropriate rice mill boiler machine is essential to ensure efficient and reliable operation. Several factors need to be considered when making this decision. Firstly, the thermal capacity of the boiler should align with the production capacity of the rice mill. It is crucial to determine the amount of steam required to meet the milling demands effectively. Secondly, the working pressure of the boiler needs to be considered to maintain optimal steam conditions throughout the process. Finally, factors such as fuel availability, energy efficiency, and environmental impact should also be taken into account.

Part 2: ZOZEN’s Best-Selling Rice Mill Boiler Machines

ZOZEN, a renowned industrial boiler manufacturer, offers a wide range of rice mill boiler machines to meet the diverse needs of the rice processing industry. Let’s explore some of their popular models:

WNS Series Steam Boiler: The WNS series boilers are fuel and gas-fired, with a thermal capacity ranging from 1 to 20 t/h. The working pressure ranges from 0.7 to 2 MPa, making them suitable for small to medium-sized rice mills.

SZS Series Steam Boiler: SZS boilers feature a D-type layout and can be fueled by oil or gas. With a thermal capacity of 2 to 110 t/h and a working pressure of 1.25 to 5.3 MPa, these boilers are ideal for larger rice mills with higher steam demands.

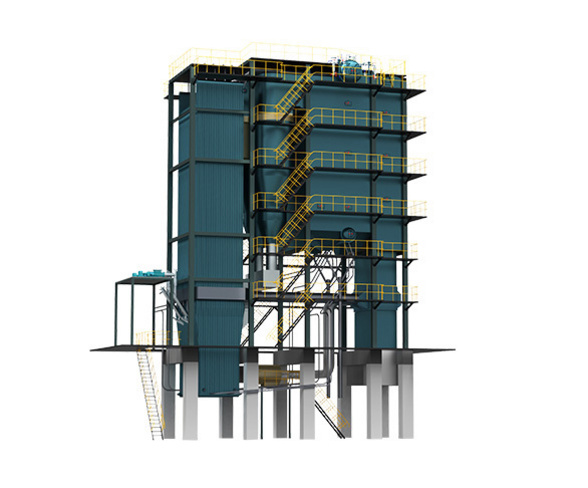

DZL Series Boiler: The DZL series consists of single drum boilers that can burn coal or biomass. They have a thermal capacity of 2 to 10 t/h and a working pressure of 1 to 2.5 MPa. These boilers are suitable for rice mills that have access to coal or biomass fuels. The DZL series also includes a three-drum biomass-fired boiler, with a thermal capacity of 15-40 t/h and a working pressure of 1.25-2.5 MPa.

ZOZEN DZL Series Single Drum Rice Mill Boiler Machine

SZL Series Steam Boiler: SZL boilers are double drum boilers designed to burn coal or biomass. With a thermal capacity ranging from 6 to 35 t/h and a working pressure of 1 to 2.5 MPa, these boilers are well-suited for large-scale rice mills.

Additionally, ZOZEN offers thermal oil boilers for rice mills:

YQW Series Thermal Oil Boiler: YQW boilers are horizontal fuel and gas-fired thermal oil boilers. They have a thermal capacity of 1400 to 14000 kW and a working pressure of 0.8 to 1.0 MPa.

YQL Series Thermal Oil Boiler: YQL boilers are vertical fuel and gas-fired thermal oil boilers. They have a thermal capacity of 7000 to 29000 kW and a working pressure of 0.8 to 1.0 MPa.

YLW Series Thermal Oil Boiler: YLW boilers are horizontal coal or biomass-fired thermal oil boilers. They have a thermal capacity of 1400 to 29000 kW and a working pressure of 0.8 to 1.0 MPa.

Part 3: Features of ZOZEN’s Rice Mill Boiler Machines

ZOZEN’s rice mill boiler machines are known for their high efficiency, durability, reliability, and energy-saving capabilities. They incorporate advanced technologies and stringent quality control measures to ensure optimal performance. These boilers are designed to maximize fuel utilization, minimize emissions, and reduce operational costs for rice mill owners. ZOZEN’s commitment to excellence is evident in their continuous research and development efforts, resulting in cutting-edge boiler solutions for the rice milling industry.

ZOZEN’s rice mill boiler machines feature advanced combustion systems, efficient heat transfer, and precise temperature control. They are equipped with state-of-the-art controls and safety devices, ensuring reliable and safe operation. ZOZEN’s boilers are manufactured using high-quality materials and undergo rigorous quality control processes to guarantee their durability and longevity.

With years of experience and expertise in manufacturing rice mill boiler machines, ZOZEN has established itself as a trusted name in the industry. Their commitment to customer satisfaction, coupled with their technical proficiency, sets them apart as a reliable partner for rice mill owners seeking efficient and reliable boiler solutions.

Conclusion

Rice mill boiler machines are indispensable in the rice processing industry. They provide the necessary steam for various stages of rice milling, ensuring the production of high-quality rice. When selecting a rice mill boiler machine, factors such as thermal capacity, working pressure, fuel availability, energy efficiency, and environmental impact should be considered. ZOZEN, a leading manufacturer, offers a wide range of rice mill boiler machines, including the WNS, SZS, DZL, and SZL series of steam boilers, as well as the YQW, YQL, and YLW series of thermal oil boilers. ZOZEN’s boilers are known for their efficiency, durability, reliability, and energy-saving features. With advanced technologies and stringent quality control measures, ZOZEN ensures that their rice mill boiler machines meet the highest standards of performance. As a trusted manufacturer with extensive experience and expertise, ZOZEN is the ideal choice for rice mill owners seeking top-quality and efficient boiler solutions.