In the industrial sector, horizontal boiler plays a pivotal role in meeting diverse energy needs. Defined as cylindrical vessels that generate steam or hot water through the combustion of fuel, these boilers are designed for efficiency and reliability. Among the leading manufacturers in this field, ZOZEN Boiler has established a strong market position, known for its innovative solutions and high-quality products. With a commitment to excellence, ZOZEN’s horizontal boilers are trusted across various industries for their performance and durability.

Advantages of Horizontal Boilers

Design and Efficiency: One of the most significant advantages of horizontal boiler is their design, which maximizes thermal efficiency. Many ZOZEN models incorporate advanced engineering techniques that enhance heat transfer and reduce energy consumption.

Reliability and Safety: Safety is paramount in any industrial operation, and ZOZEN’s horizontal boilers are equipped with advanced safety control systems. These systems monitor various parameters, ensuring optimal operation while preventing potential hazards. Additionally, the quality assurance measures taken during manufacturing guarantee the durability of each boiler. As a result, ZOZEN’s horizontal boilers are not only reliable but also built to withstand the rigors of continuous operation, further solidifying their reputation in the market.

ZOZEN’s Horizontal Boiler Offerings

Oil and Gas-Fired Horizontal Boilers

ZOZEN offers a range of horizontal boilers designed to run on oil and gas. The WNS series includes three-pass wet-back fuel oil/gas boilers with thermal capacities ranging from 1 to 20 tons per hour (t/h) and working pressures from 0.7 to 2 MPa. These boilers are equipped with advanced control systems, enabling unattended operation.

The SZS series features a double-drum, horizontal design with a D-type layout. This series offers thermal capacities from 2 to 110 t/h and working pressures from 1.25 to 5.3 MPa. The membrane water-cooled wall and large furnace design in these horizontal boilers improve heat transfer efficiency significantly.

For applications requiring thermal oil, the YQW series provides horizontal thermal oil boilers with capacities from 1400 to 14,000 kW and working pressures between 0.8 and 1.0 MPa. These units ensure precise control of oil temperature and pressure, contributing to operational safety.

Biomass and Coal-Fired Horizontal Boilers

For industries looking to use biomass or coal, ZOZEN has developed several models. The SZL series is a double-drum chain grate water tube boiler, providing thermal capacities of 6 to 35 t/h and working pressures from 1 to 2.5 MPa. Its compact design with closely spaced water-cooled wall tubes maximizes the radiation area.

The DZL series, a three-pass water-fire tube chain grate boiler, offers capacities from 2 to 10 t/h and working pressures from 1 to 2.5 MPa. It features lightweight chain grates for easy installation and operation, which makes these horizontal boilers particularly user-friendly.

The DHL series, an angle tube boiler, ranges from 20 to 75 t/h with pressures of 1.25 to 5.4 MPa. Its robust construction with a beam-type chain grate ensures complete combustion of fuels.

Lastly, the YLW series provides horizontal coal-fired and biomass thermal oil boilers with thermal capacities between 1400 and 29,000 kW, operating at pressures from 0.8 to 1.0 MPa. These horizontal boilers are equipped with advanced control systems for precise operation.

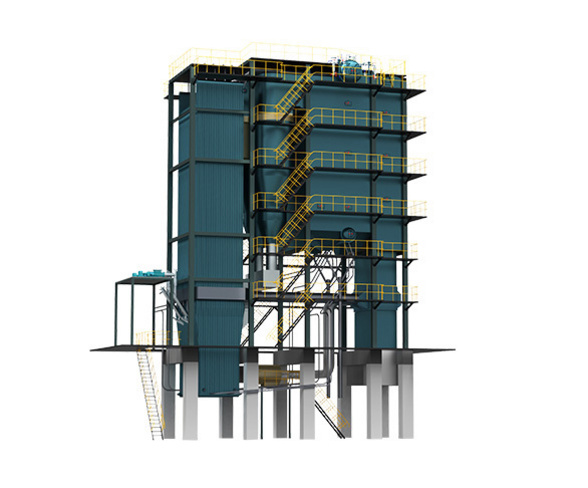

Additionally, ZOZEN has developed a unique biomass steam horizontal boiler, the DZL series, which features a soot-blowing device in its design. This innovative boiler, with a thermal capacity of 15 to 40 t/h and working pressures from 1.25 to 2.5 MPa, allows for cleaning without shutting down the unit, enhancing operational efficiency.

ZOZEN DZL Series Biomass Fired Horizontal Boiler

Key Features of ZOZEN’s Horizontal Boilers

ZOZEN’s horizontal boilers stand out due to their high thermal efficiency, low emissions, and sturdy construction. With user-friendly designs and advanced smart control systems, these boilers simplify operation and maintenance. ZOZEN’s innovative combustion technologies further optimize fuel utilization, ensuring that their horizontal boilers not only meet but exceed industry standards.

Conclusion

ZOZEN’s commitment to innovation and quality makes their horizontal boilers a top choice for industrial applications. With a diverse range of options tailored to various fuels and operational needs, ZOZEN continues to lead the market in providing efficient and reliable boiler solutions. For industries seeking performance and reliability, ZOZEN’s horizontal boilers offer the ultimate solution to their energy requirements.