Part 1: Analysis of Global Economic Fluctuations and Increasing Costs in the Boiler Industry

In recent years, the global economic situation has experienced significant fluctuations. Coupled with the rising prices of raw materials and increasingly stringent environmental regulations, the boiler industry has faced mounting cost pressures. Various aspects such as steel, fuel, and labor costs have witnessed notable increases, leading to a significant rise in production and operational costs of traditional boilers.

As the demand for energy-efficient and environmentally friendly solutions grows, industrial boiler manufacturers face the challenge of developing new system boilers that can meet these requirements while maintaining competitive pricing. One such company that has excelled in this area is ZOZEN (Zhongzheng) Boiler.

Part 2: Introduction to ZOZEN Boiler and the Relevance of Cost of New System Boilers

ZOZEN Boiler is a renowned manufacturer specializing in industrial boilers. With a strong emphasis on quality and customer satisfaction, ZOZEN offers a range of cost-effective new system boilers tailored to meet the diverse needs of clients. The company understands the significance of cost in the decision-making process and strives to provide boilers that deliver value for money.

ZOZEN’s cost of new system boiler is backed by its commitment to innovation and optimized design, resulting in improved energy efficiency and reduced operational costs. The company invests significant resources in research and development to enhance the performance and cost-effectiveness of its new system boilers.

Part 3: ZOZEN’s High-Quality Industrial Steam Boilers

ZOZEN offers high-quality industrial steam boilers categorized by fuel type. For oil and gas, the WNS series and SZS series are available. The WNS series industrial steam boiler is a three-pass wetback oil/gas-fired boiler with a thermal capacity ranging from 1 to 20 t/h and a working pressure of 0.7 to 2 MPa. It incorporates an advanced control system for unmanned operation.

The SZS series industrial steam boiler features a double-drum, horizontal, D-type layout with a thermal capacity ranging from 2 to 110 t/h and a working pressure of 1.25 to 5.3 MPa. Its membrane water-cooled wall and spacious furnace design enhance heat transfer efficiency.

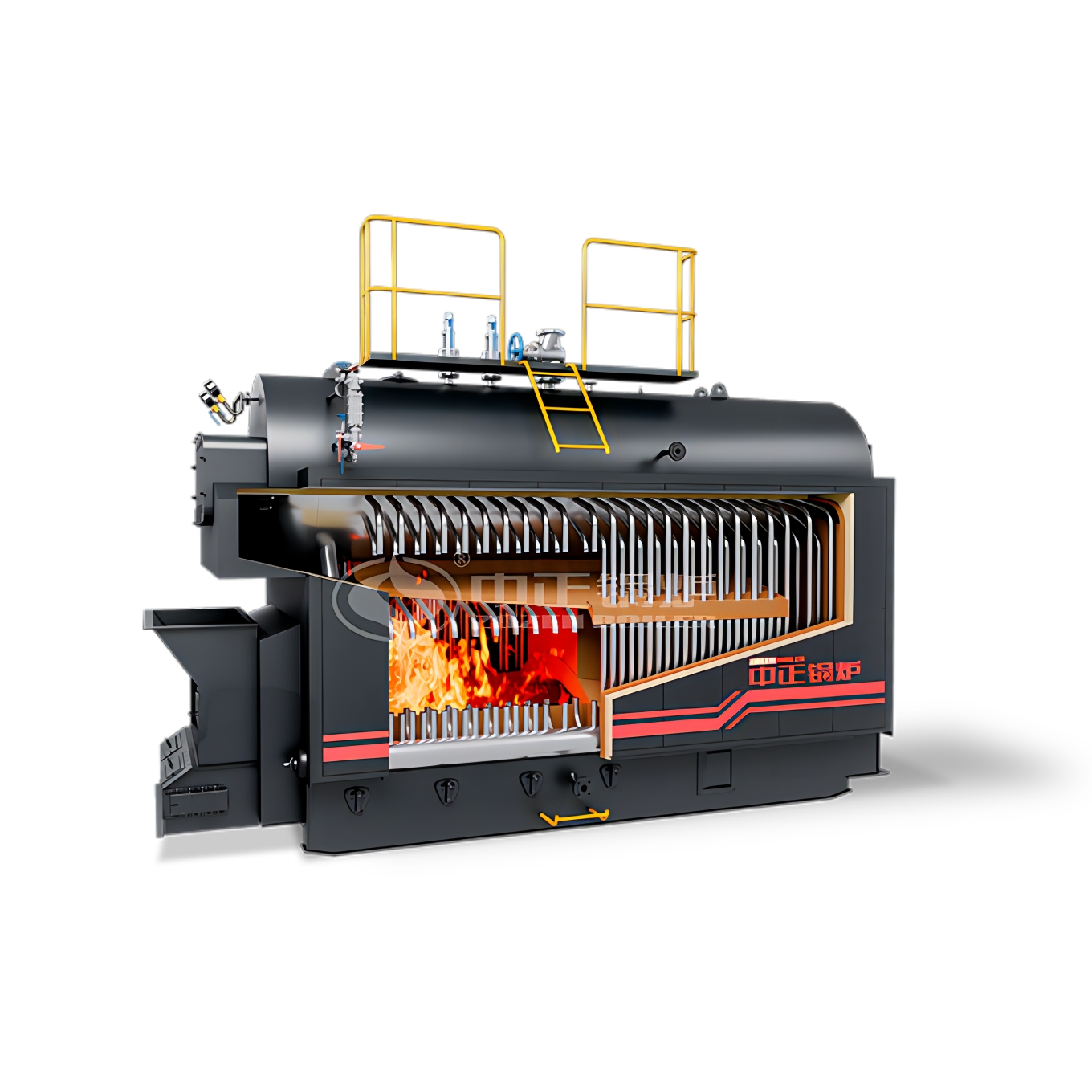

ZOZEN SZS Series Gas Fired New System Boiler

For biomass and coal fuels, ZOZEN offers the SZL, SHX, DZL, DHL, and DHX series. The SZL series industrial steam boiler is a horizontal, double-drum, chain grate boiler with a thermal capacity ranging from 6 to 35 t/h and a working pressure of 1 to 2.5 MPa. Its furnace adopts a densely arranged water-cooled wall tube structure, providing a large radiation heating area.

The SHX series industrial steam boiler is a circulating fluidized bed boiler with a thermal capacity ranging from 10 to 75 t/h and a working pressure of 1.25 to 2.45 MPa. It offers broad fuel adaptability and high combustion efficiency, making it particularly suitable for low-calorific-value coal.

The DZL series industrial steam boiler is a horizontal, three-pass, water-fire tube chain grate boiler with a thermal capacity ranging from 2 to 10 t/h and a working pressure of 1 to 2.5 MPa. Its electrical control enables stepless grate speed adjustment, along with comprehensive parameter alarms and interlock protection.

The DHL series industrial steam boiler is a corner tube boiler with a thermal capacity ranging from 20 to 75 t/h and a working pressure of 1.25 to 5.4 MPa. It features a beam-type chain grate and membrane water-cooled wall structure, ensuring thorough fuel combustion.

The DHX series industrial steam boiler is a circulating fluidized bed boiler with a thermal capacity ranging from 35 to 75 t/h and a working pressure of 1.25 to 5.3 MPa. The boiler produces highly active ash residue, facilitating comprehensive utilization without secondary ash pollution.

Additionally, ZOZEN has independently developed a biomass boiler with proprietary intellectual property rights, the DZL series horizontal water tube biomass steam boiler. It has a thermal capacity of 15 to 40 t/h and a working pressure of 1.25 to 2.5 MPa. The boiler is equipped with an ash blowing device at the rear and an ash blowing hole at the top, allowing ash cleaning without the need to stop the boiler.

Part 4: Highlighting ZOZEN’s Cost of New System Boilers’ Advantages

ZOZEN’s new system boilers offer several product features that provide cost cost of new system boiler’s advantages:

Intelligent control system: The automation of boiler operations reduces labor cost of new system boiler.

High-efficiency combustion technology: Improved fuel utilization reduces fuel cost of new system boiler.

Environmentally friendly design: Compliant with the latest environmental standards, the boilers reduce emissions and lower environmental cost of new system boiler.

ZOZEN offers a diverse selection of boilers based on different fuel types, including oil, gas, biomass, and coal. The company’s cost of new system boilers is optimized through intelligent control systems, high-efficiency combustion technology, and environmentally friendly designs. By prioritizing energy efficiency and reducing operational costs, ZOZEN ensures that its boilers provide a competitive edge to clients.

Conclusion

ZOZEN’s cost of new system boiler addresses the challenges posed by rising costs in the industrial boiler industry. Through continuous innovation, advanced technologies, and a commitment to customer satisfaction, ZOZEN provides cost-effective and high-quality solutions that meet the demands of a changing economic and environmental landscape.