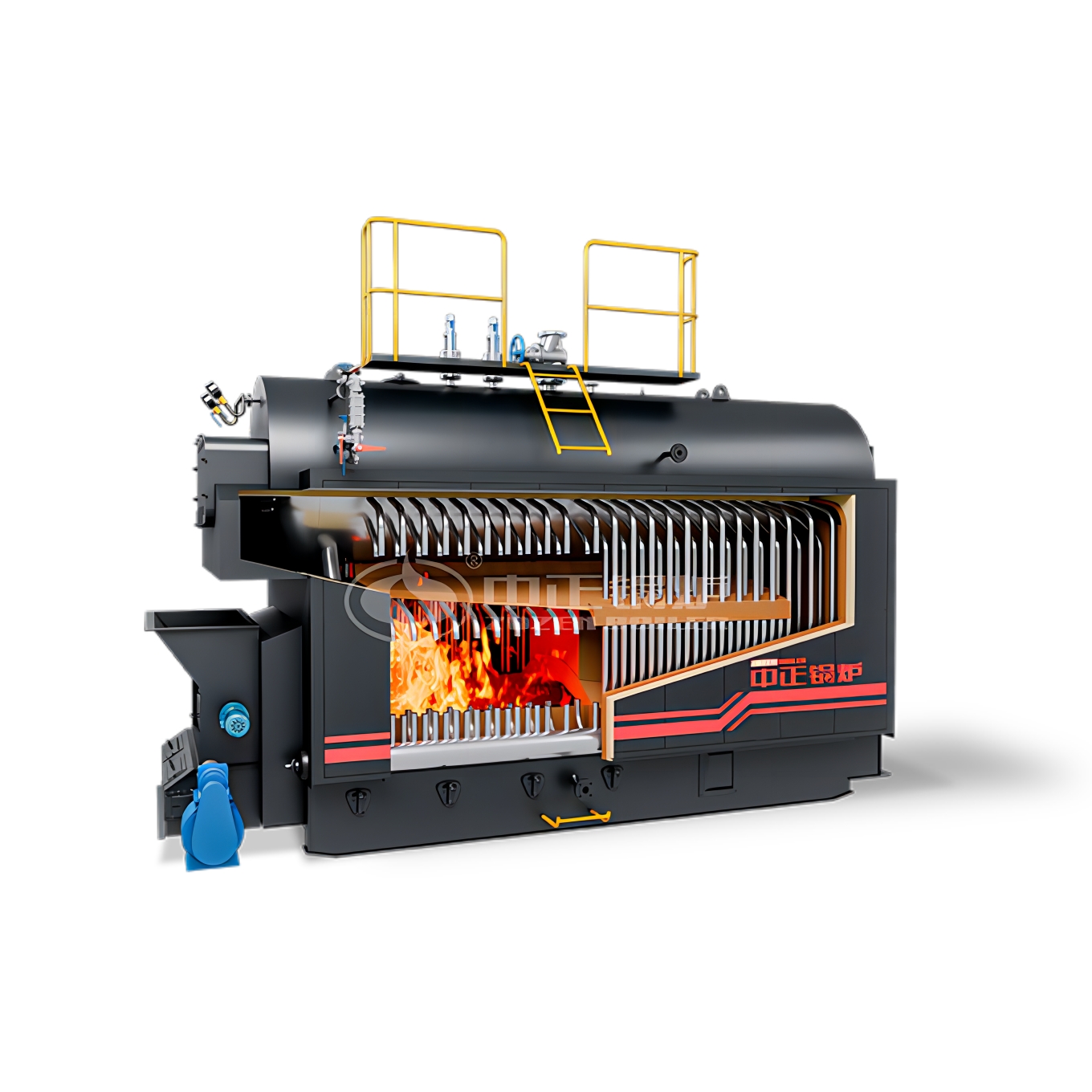

SZL series biomass boiler structure design is reasonable, combustion mode is chain grate, burning biomass molding fuel. Hot water boiler manufacturing have water cooling wall structure. The water wall pipes of the front and rear walls of the biomass hot water boiler extend downward to the upper part of the grate to form the front and rear arches. This structure not only increases the sealing performance of the boiler, but also increases the furnace volume and heating surface, and at the same time strengthens the strength of the rear arch.

SZL series chain grate biomass boiler has high automation level, safe and stable operation, strong fuel applicability and high smoke emission standard. After the hot water boiler manufacturing furnace for the combustion chamber, convection tube bundle, the tail has economizer. The flue gas passes through the furnace, burnout chamber, convection tube bundle and economizer into the tail flue, and is discharged into the atmosphere through dust collector, induced draft fan and chimney. The front wall is equipped with secondary air, controlled by the valve, which is put into use when burning biomass fuel, intensifying combustion, making fuel burn out fully and improving combustion efficiency. A higher feed inlet is used to meet the demand for biomass fuel.

The industrial biomass boiler adopts two sides of air inlet, and sets independent air chamber along the vertical of the grate, and each air chamber has independent air regulating device, which can adjust the air volume of each air chamber respectively, so as to achieve the regulation effect of combustion. The inverted “” furnace arch technology is adopted, the front arch is high and short, the back arch is low and long, which increases the burnout time of flue gas in the furnace and improves the combustion efficiency. The streamlined rear arch can throw the unburned carbon particles blown from the middle and back of the grate into the forward part, making the coal easier to ignite. The ignition line is neat and the coal has wide applicability.

The SZL series hot water boiler adopts shorter furnace arch and secondary air as well as larger furnace volume to promote fuel combustion fully and effectively in the furnace according to the characteristics of biomass fuel combustion. This boiler has two parts leaving the factory, easy to install and move. After assembling the boiler leaving the factory, it only needs to combine the two parts, lay the upper and lower furnace wall, install the auxiliary machine system such as slag extractor, fan and smoke duct, and connect the water and electricity to run, easy to install and short cycle.

Hot water boiler manufacturing structure is compact, occupies a small area, the boiler only needs a single layer layout, so the civil engineering investment is less. The water wall tube is closely arranged, which can effectively reduce the temperature of the furnace wall on both sides. Therefore, the light furnace wall can be used after the water wall on both sides, which can effectively reduce the transport weight, and has the characteristics of fast starting and rising fire. Zozen Boilers production various types of industrial boiler products, can also according to customer demand for custom service one-on-one boiler, welcome everyone to come to advisory procurement.