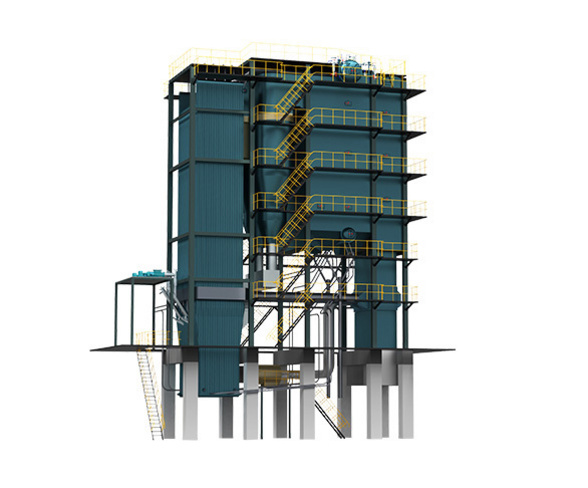

Maintenance of hot water boiler 10mw introduction

Hot water boiler as heating equipment, with its steel consumption less material requirements low, energy saving, heating area, heating effect is good and more and more advantages are used by people. However, in the regular inspection of the boiler, the author found that many units do not pay enough attention to the maintenance of the hot water boiler. For example, some boilers do not do maintenance after the boiler is stopped, some although the maintenance, but due to improper methods, the reverse boiler metal produces serious corrosion, and the hot water boiler during the shutdown of the corrosion is much more serious than the operation of the corrosion. Therefore, it is a problem that cannot be neglected to strengthen the maintenance of the hot water boiler during the shutdown period and extend the service life of the boiler. Should cause to use unit and concerned branch enough attention.

Corrosion location and characteristics of hot water boiler during shutdown

After the hot water boiler is shut down, if the reasonable maintenance method is not taken, just put the furnace water or fill it with raw water, abandoned, the result is that the metal of the pressurized parts will be seriously corroded.

Corrosion usually occurs at the bottom corner of the furnace bottom of the vertical boiler; The bottom of the water tube boiler and the lower part of the collecting box where the furnace water is put; The bottom of the shell of a horizontal boiler, especially the outer wall of the smoke pipe. When viewed from the outside, these corrosion products are formed on the metal surface in different sizes, with a diameter of 5-25mm and a height of 4-10mm. The color of the surface of the scar varies from yellowish-brown to brick-red, and the surface is peeled open, with a black powder inside. When these corrosion products are removed, uneven pits appear on the metal walls. Its depth is generally 0.5-4mm and its diameter is 4-8mm. In addition, if there is no cleaning in the furnace and flue, and no moisture absorbing agent is placed, the moisture in the air along the brick wall, due to capillary action to penetrate into contact with the boiler pressure components, will also cause corrosion.

For detailed boiler quotes, you can consult online customer service or email me lexie@zozen.com.