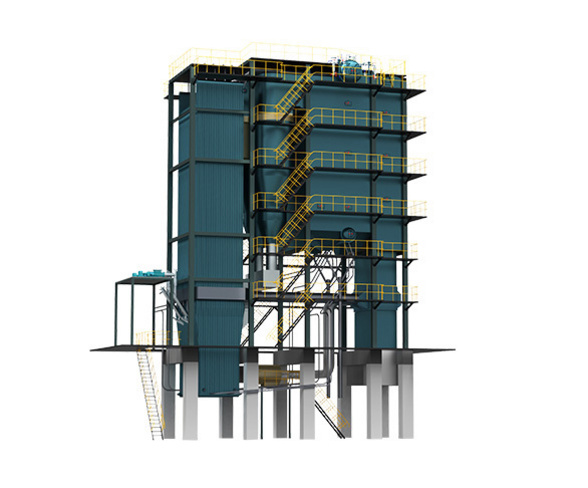

Zhongzheng industrial condensing boiler is a new type boiler with high thermal efficiency, low energy consumption rate, remarkable energy saving effect, low smoke resistance and low pollution caused by smoke to the environment. It is a kind of compact structure, easy to use, long service life, safe and reliable operation, high degree of automation environmental protection heating equipment.

The conventional gas (oil) boiler can only achieve 85%~92% thermal efficiency, and the smoke exhaust temperature is 140~ 250℃. As a result, the water generated during fuel combustion is in the state of overheating in the flue gas, and the steam is lost from the chimney with the flue gas. The industrial condensing gas boiler uses the principle of releasing a large amount of latent heat of vaporization in the process of water vapor condensation into liquid water, and reduces the exhaust temperature to 50~70℃ by setting up a flue gas waste heat recovery device, fully recovering the sensible heat in flue gas and latent heat of water vapor condensation, and the theoretical value of thermal efficiency can reach up to 109%.

Generally speaking, the boiler with thermal efficiency of more than 100% is difficult to understand in common sense, but if the latent heat of condensation of water steam in the flue gas is used, and the exhaust temperature is lowered low enough, the exhaust smoke loss is very low, the thermal efficiency of the boiler will be increased to 100%, or even more than 100%.

Advantages of industrial condensing boiler

- Efficient finned tube energy saver (high temperature water supply heater) and corrosion-resistant high efficiency finned tube condensing heat exchanger (low temperature water supply preheater) were used to effectively reduce the exhaust temperature and improve the boiler thermal efficiency (up to or even more than 100%).

- The condensing boiler structure adopts the highly integrated technology, highly integrates the heating surface of the body and the low-temperature extension heating surface (energy saver and condenser), which makes the boiler structure compact and occupies a small area, saves the construction land and construction cost of the boiler room, and simplifies the on-site installation workload.

- The harmful gas of the flue gas is effectively controlled and flows into the neutralization pool with the condensate.

To sum up, condensing boiler is the crystallization of heat transfer, physics, combustion, materials science and other sciences. It is superior to traditional boilers in absolute economy. The popularization of condensing boiler is a shining of field thinking and a change of concept, and it will certainly promote the development of thermal industry.