How much will you spend on the industrial heating system for your facility?

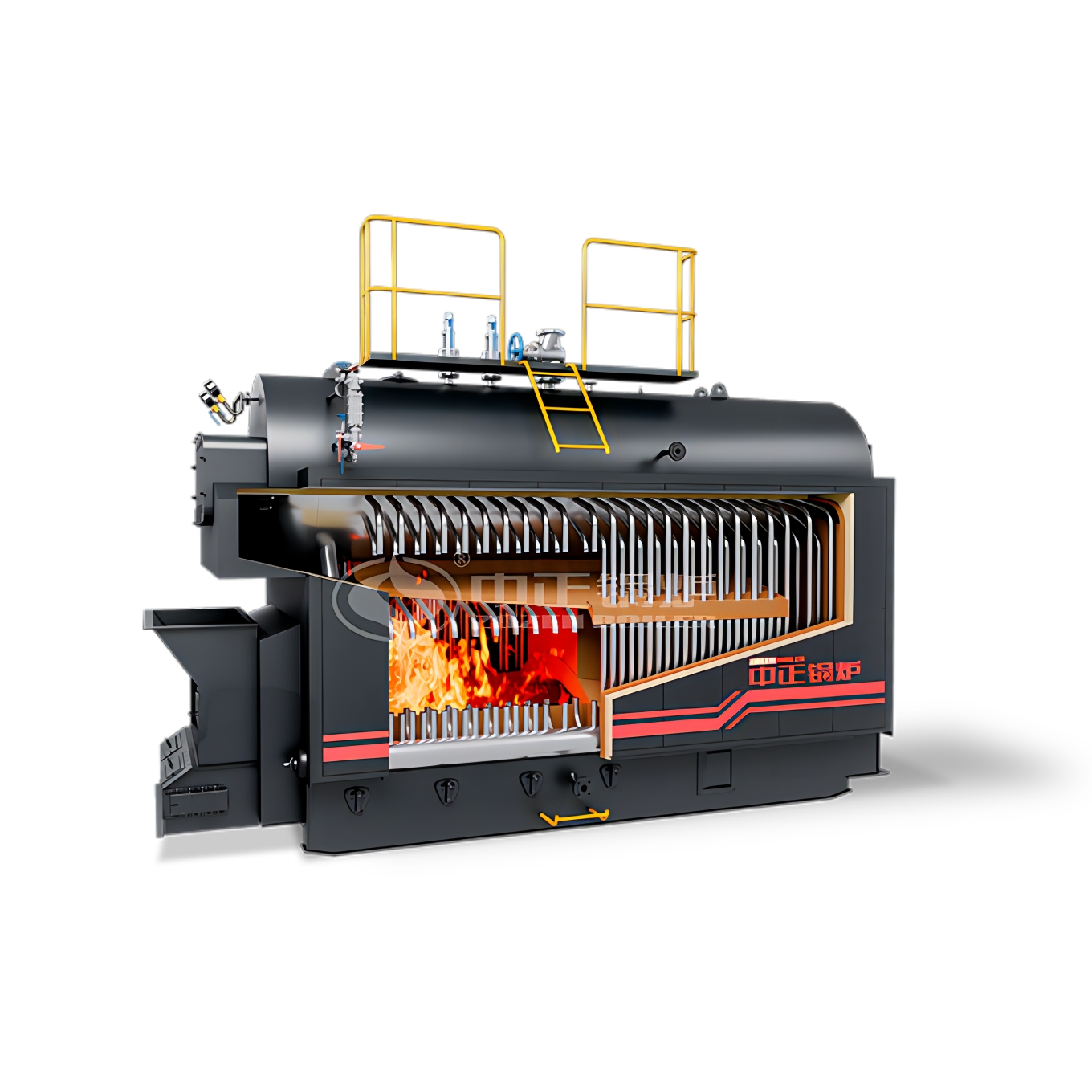

A boilers is an industrial device that not directly contacted by most people, but is closely related to our daily lives. Winter heating supply, steam sterilization for food or medical instruments and thermal energy for various types of factories all require industrial boilers.

When it’s time to purchase a new piece of industrial boiler equipment, one of the first questions on most facility managers’ minds is: How much is this going to cost? However, this is a big mistake that some customers use low price to blindly measure whether to buy a boiler product. Price is important, but it is not a decisive factor. There are many other important information that we need to learn and compare.

The first to consider is boiler thermal efficiency. Industrial boilers are important energy conversion facilities in production, and boiler thermal efficiency determines the operating costs of the facility, and the thermal efficiency of the boiler is directly related to the manufacturer’s design level. That is to say, a high-performance boiler can save the cost of the boiler proper in one year!

Secondly, the manufacturer’s manufacturing ability is an important factor to consider whether an enterprise can ensure delivery conditions in quality,time and cost. Enterprises with strong manufacturing capabilities can guarantee both product quality and production cycle.

Boiler for the textile industry advantage

Then it comes to save investment costs through reasonable selection. The complete set of quotation for industrial boilers consists of the price of the boiler proper and the auxiliaries,the installation cost, transportation cost, etc. Read on to find out 6 factors that influence the cost of the ZOZEN industrial heating system.

Notice: In the future, ZOZEN will continue to be committed to the upgrading of industrial boilers, and promote the high-quality development of the fruit and vegetable juice industry!