DHL corner tube boilers originated in Germany, after the improvement of multinational experts, has now formed a large boiler series. It is widely used in chemical industry, papermaking, textile, food, heating and many other fields. Currently Zozen Boilers are mainly to burn coal and biomass, two series of various parameters of steam, hot water boiler, the steam boiler capacity: 20-75 t/h, 1.25 5.4 MPA pressure, superheated steam temperature can be selected according to the customer. The power of hot water boiler is 1.4-14MW, and the output and return water temperature can be selected from 130°C/70°C and 150°C/90°C according to customer requirements.

In recent years, with the strengthening of energy conservation and emission reduction, the use of renewable energy has been attached great importance. Corner tube boilers for the full film wall structure, pot cylinder in the furnace outside, not heated, the furnace is high and wide, and equipped with secondary air, biomass burning is very favorable. Relative to the circulating fluidized bed biomass boiler, DHL series coal-fired steam boiler has less investment, short time limit, simple operation, low failure rate and little difference in boiler operating efficiency. Therefore, the development prospect of large-scale corner tube boiler is broad.

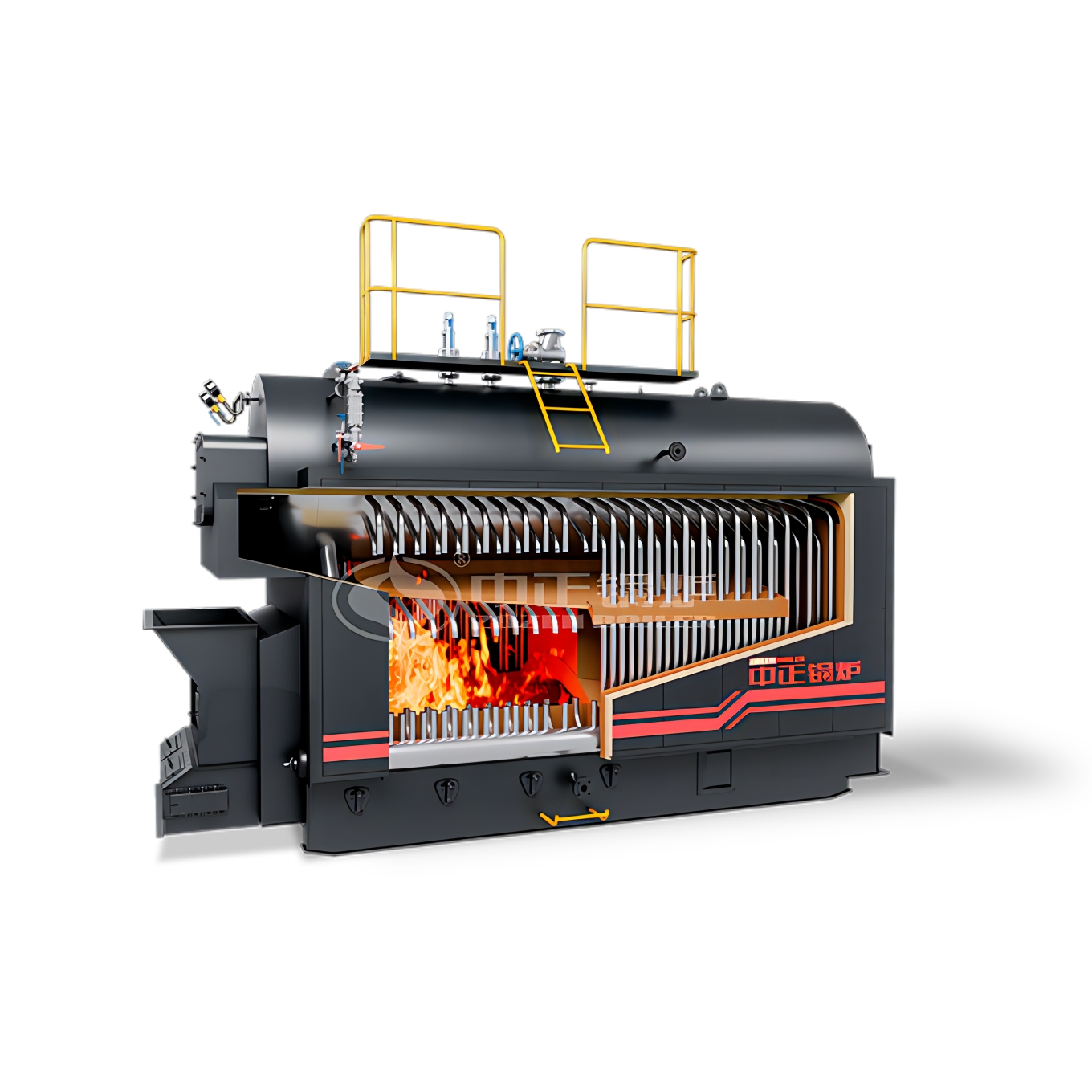

Corner tube boiler manufacturer adopts unique water circulation system, boiler thermal efficiency is high and safe and reliable. Corner tube boiler is self-supporting structure, no steel frame, saving metal consumption. It adopts the structure of beam type chain grate with equal pressure to supply air to the storehouse, which is suitable for wide coal design. Corner tube boiler installation workload is less, installation cycle is short, construction cost is low. Economizer or air preheater is arranged at the rear of the boiler. Since the flue gas discharge temperature from the boiler body is still relatively high, the tail of the economizer or air preheater can absorb the heat of the flue gas, reduce the exhaust temperature of the flue gas, save energy and improve efficiency.

This series of industrial DHL boiler furnace wall is light insulation furnace wall. The light heat preservation structure of the furnace wall, the outer layer of the water cooling wall is laid with certain thickness of heat preservation materials, and the outer layer is covered with outer protection plate. The boiler starts and runs with small heat storage of the furnace wall, good heat preservation performance of the boiler, small loss, and beautiful and neat appearance. Depending on the fuel, secondary air can also be arranged on the front wall and rear wall of the furnace.

ZOZEN Boilers are of high quality boiler manufacturers, we are committed to improve the boiler with high quality service for the customer, the specific solution of boiler, boiler offer reasonable. Welcome to our factory to consult and purchase, we will serve you wholeheartedly.