Part 1: The Importance of Paddy Boiler Machine in the Rice Field

Paddy boiler machines play a critical role in the rice field industry, specifically designed for the processing of paddy rice. These industrial boilers generate steam, which is essential for various stages of rice milling. The paddy boiler machine efficiently removes the husk from rice grains, resulting in polished white rice that is ready for consumption.

Part 2: Factors Affecting Paddy Boiler Machine Price

The paddy boiler machine price is influenced by various factors that reflect its specifications, features, and overall quality. Understanding these factors can help rice millers make informed decisions when purchasing a paddy boiler machine. Here are some key factors that affect the paddy boiler machine price:

Capacity: The capacity measured in terms of thermal capacity or the amount of steam it can generate per hour, is a significant factor in determining the paddy boiler machine price. Generally, higher capacity machines that can process larger quantities of paddy rice will have a higher price tag. The larger the capacity, the more robust and efficient the machine needs to be, which contributes to the increased cost.

Working Pressure: The working pressure is another factor that affects the paddy boiler machine price. Machines designed to operate at higher pressures require stronger and more durable materials to withstand the increased stress. As a result, boilers with higher working pressures tend to be more expensive compared to those with lower working pressures.

Automation and Technology: The level of automation and technology can significantly impact the paddy boiler machine price. Advanced features such as automatic temperature control, precise monitoring systems, and energy-efficient components can drive up the cost. These technological advancements enhance the efficiency and performance of the machine, resulting in more precise control over the rice milling process.

Brand Reputation and Quality: The brand reputation and the overall quality play a crucial role in determining the paddy boiler machine price. Well-established brands with a track record of manufacturing reliable and high-quality machines often command higher prices. These brands invest in research and development, ensuring that their products meet industry standards and customer expectations. Choosing a reputable brand ensures a higher level of reliability, durability, and after-sales support, which can justify the higher price.

Material and Construction: The materials used in the construction of the paddy boiler machine can impact its price. High-quality materials, such as stainless steel or corrosion-resistant alloys, are more expensive but offer better longevity and performance. The construction of the machine, including the design, welding quality, and overall workmanship, also contributes to its price. Well-engineered and precisely constructed boilers tend to have a higher price due to the attention to detail and superior craftsmanship involved.

By considering these factors, rice millers can assess the features and specifications they require in a paddy boiler machine and make an informed decision based on their budget and specific needs. It is crucial to strike a balance between the price and the quality to ensure long-term reliability and efficient rice processing operations.

Part 3: ZOZEN’s Paddy Boiler Machine

ZOZEN is a renowned manufacturer of paddy boiler machines that offers a range of series to meet customer requirements.

SZL Series: Double-Drum Paddy Boiler Machine

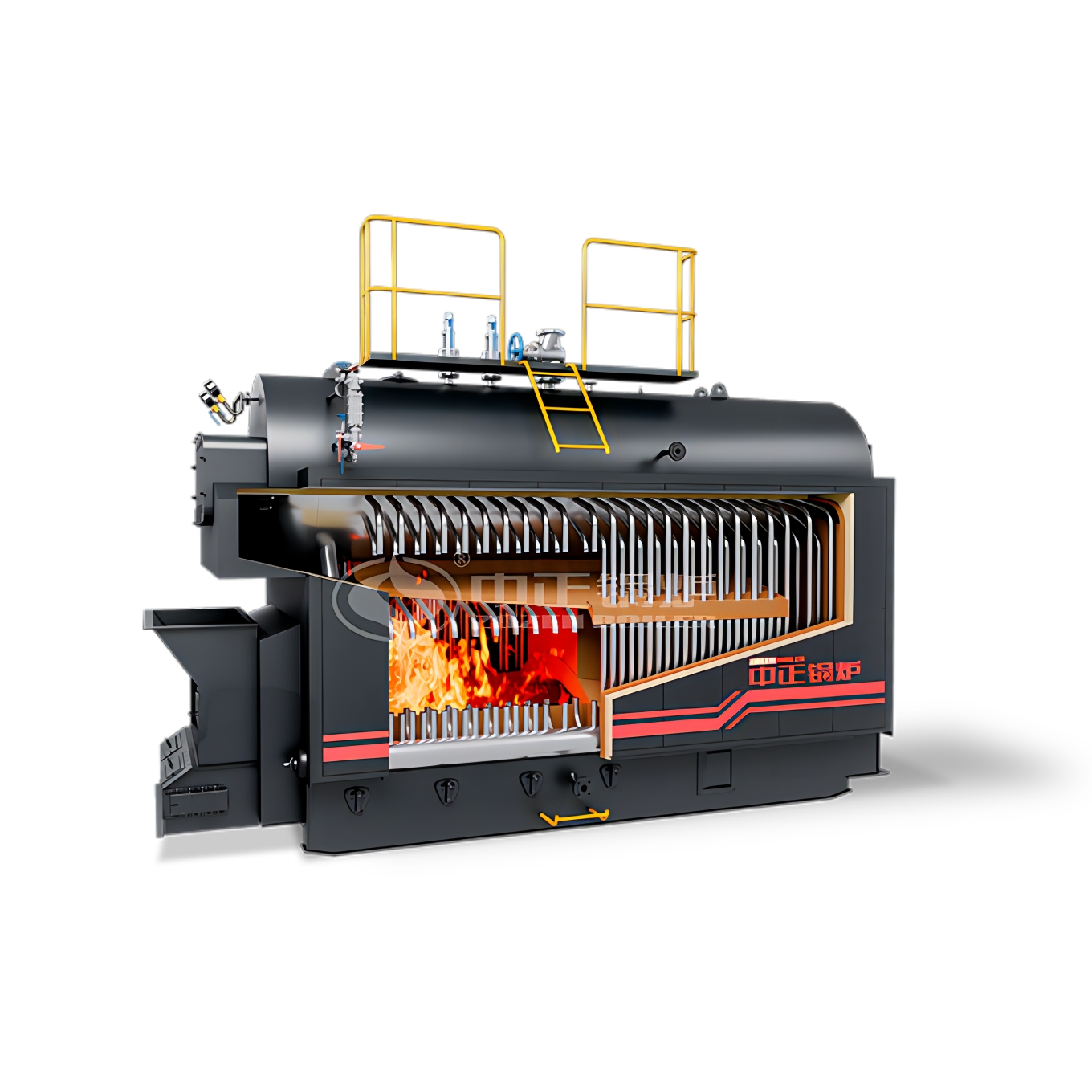

The SZL series is a double-drum paddy boiler machine with a thermal capacity ranging from 6 to 35 t/h and a working pressure of 1 to 2.5 MPa. It is designed to provide efficient steam generation for large-scale rice milling operations. The SZL series is known for its durability, high combustion efficiency, and ease of operation.

ZOZEN SZL Series Paddy Boiler Machine

DZL Series: Single and Triple-Drum Paddy Boiler Machine

ZOZEN’s DZL series comprises two types of paddy boiler machines. The single-drum DZL series has a thermal capacity of 2 to 10 t/h and a working pressure of 1 to 2.5 MPa. It offers a compact design and easy installation, making it suitable for smaller rice mills. The tri-drum DZL series, independently developed by ZOZEN, boasts a thermal capacity of 15 to 40 t/h and a working pressure of 1.25 to 2.5 MPa. These machines are known for their high efficiency, low emissions, and reliable performance.

DHL Series: Corner Tube Paddy Boiler Machine

ZOZEN’s DHL series is a corner tube paddy boiler machine, designed for larger rice milling operations. It has a thermal capacity ranging from 20 to 75 t/h and a working pressure of 1.25 to 5.4 MPa. The DHL series offers exceptional fuel adaptability and stable operation, making it suitable for demanding processing needs.

YLW Series: Thermal Oil Paddy Boiler Machine

ZOZEN’s YLW series is a thermal oil boiler specifically designed for rice milling applications. With a thermal capacity ranging from 1400 to 29000 kW, a working pressure of 0.8 to 1.0 MPa, and an outlet temperature of 320 °C, it provides precise temperature control and stable heat supply for efficient rice drying and processing.

Part 4: ZOZEN’s Competitive Advantage in Paddy Boiler Machine Price

ZOZEN’s paddy boiler machine price is determined based on customer requirements. The company offers customized solutions, ensuring that customers pay for the features and capacity they truly need, optimizing cost-effectiveness. With a strong reputation for producing high-quality machines, ZOZEN provides a competitive advantage in terms of reliability, performance, and durability. By incorporating advanced technology, energy efficiency, and precise control systems, ZOZEN’s paddy boiler machines are trusted by rice millers worldwide.

Conclusion

Paddy boiler machines are indispensable in the rice field industry, and their prices are influenced by factors such as capacity, working pressure, automation level, brand reputation, and material quality. ZOZEN’s paddy boiler machines, including the SZL, DZL, DHL, and YLW series, offer a wide range of options to meet diverse customer needs. With their competitive advantage in customization and quality, ZOZEN’s paddy boiler machines are trusted and preferred by rice millers, ensuring efficient steam generation and optimal rice processing.