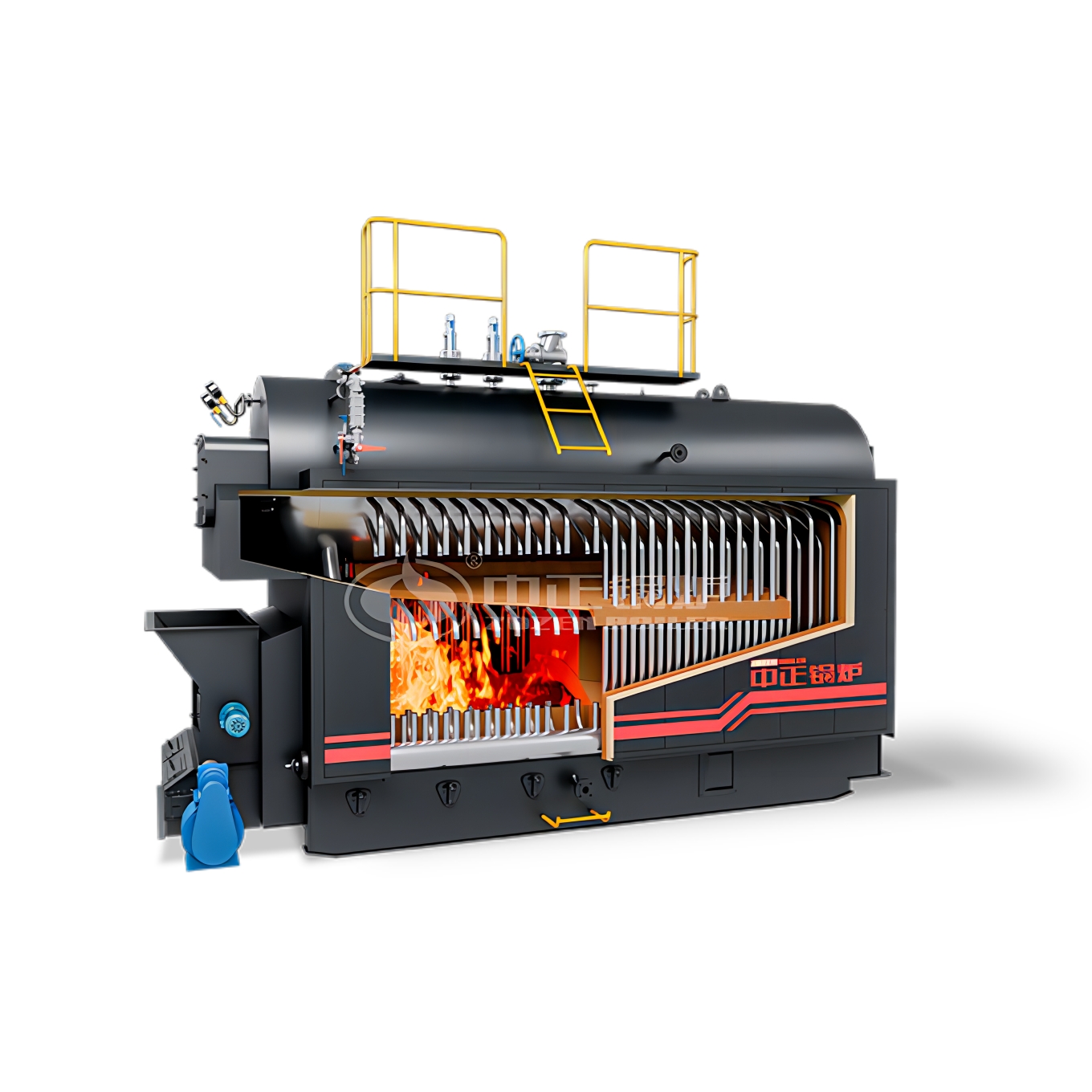

The SZL series biomass hot water boiler is a bi-drum boiler with a longitudinal construction and has natural circulation. It comes with a cast iron economizer at the end of the boiler. The SZL series biomass fired hot water boilers manufactured by our company was exported to a community of Luoyang for hot water and heating supply in winter.

This series boiler adopts high efficient thermal insulation material, low boiler surface temperature, negligible heat loss. The boilers are manufactured in strict accordance with national norms and standards, and all pressurized parts are made of high-quality boiler steel. Each boiler undergoes rigorous inspection and testing, including hydrostatic testing and X-ray inspection, before leaving the factory. Manhole, inspection door, fire-viewing hole, etc. are set up for easy maintenance. The most important features of biomass boilers are: energy saving, environmental protection, and easy to install and use.

The boiler can be equipped with oil (gas) ignition burner to realize automatic ignition. The feeding, combustion, slag removal, water supply and ignition of the boiler can all be controlled automatically, which is very convenient for operation. The boiler is equipped with an automatic ash cleaning device, which can promptly remove the accumulated ash on the heated surface of the boiler to ensure the efficient and stable operation of the boiler. The boiler is equipped with a coal economizer at the end of the boiler, and an air preheater can also be arranged according to user needs. Compared to traditional boilers, SZL biomass hot water boiler has higher efficiency and lower smoke exhaust temperature.

7MW biomass fired boilers specifications:

Capacity: 7MW

Rated pressure: 1.0MPa

Outlet water temperature: 95℃

Feed water temperature: 70℃

Design fuel: biomass pellet

Bi-drum biomass hot water boiler features:

- The biomass boiler combustor has multi-fuel capacity, it can burn rice husk, bagasse, wood, biomass pellet, and co-firing with coal.

- Economizer is made of cast-iron tubes with improved design for better heat transfer efficiency.

- The 7MW hot water boiler comes with an ash remover to collects ash at the end of the grate and brings it to the surface from where it can be collected.

- Compact structure and easy installation ensure efficient, clean, economic, safe and stable boiler operation, thus providing the users with energy-saving and environment-friendly thermal power equipment for daily and manufacturing use.

The efficiency of biomass boilers is generally above 80%, and boiler models are larger and burn more fully. The highest reached 88.3%, 15% higher than the average efficiency level of coal-fired boilers. Any interested, feel free to contact us!