Pulping, preparation, papermaking and post-processing in the papermaking process are all inseparable from the help of industrial biomass fired boilers. According to ZOZEN’s cooperation experience with various enterprises in the paper industry for many years, most paper mills use steam boilers. Industrial biomass fired steam boilers are required to provide a large amount of energy for the cooking of the separated fibers in the papermaking process, as well as subsequent washing, bleaching, and concentration steps.

Biomass fired boilers are important production equipment for paper mills, providing the necessary steam for the dry paper process. In the past, paper mills mostly used coal-fired steam boilers for production. However, with the development of production technology, enterprises began to pursue green development and began to use clean gas boilers such as gas steam boilers and biomass steam boilers for production. Among so many boilers, many paper mills use green-grade biomass steam boilers for production. The 15-ton biomass steam boiler is a common type of furnace used in paper mills.

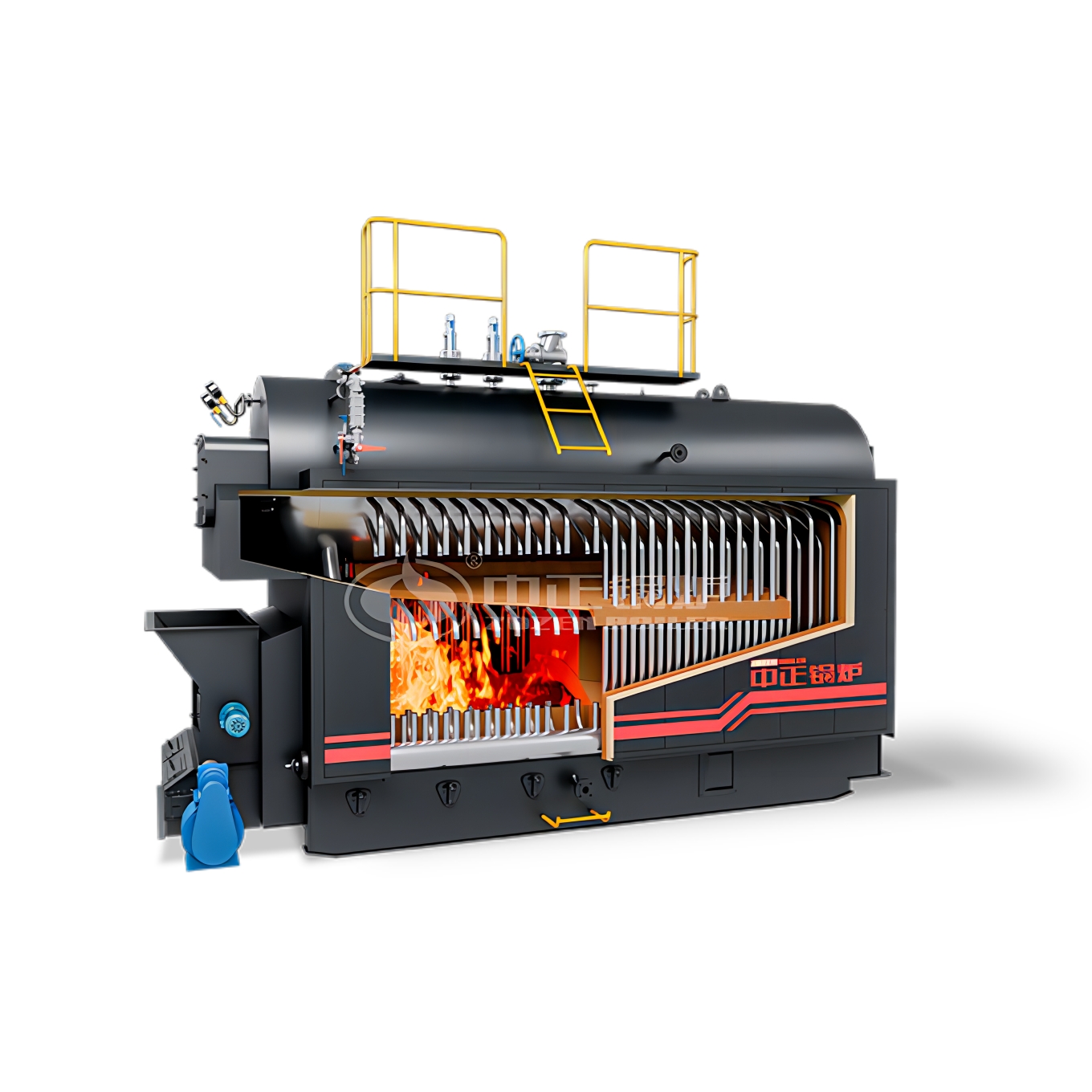

The 15-ton biomass fired steam boiler uses biomass pellets made from straw, rice straw, bagasse and other agricultural and forestry wastes as fuel, and the fuel cost is lower than other boilers. In addition, the boiler has the advantages of high thermal efficiency, perfect protection function, convenient operation and durability. It is an energy-saving and environmentally-friendly product, which is very suitable for paper mills.

The quotation of the 15-ton SZL series biomass steam boiler is mainly composed of two parts: the main engine price and the auxiliary machine price. Among them, the price of the mainframe is almost the same, and the price of the auxiliary machine is different due to the specific configuration. Therefore, the price of a 6-ton biomass steam boiler is also different.

The paper mill operates an advanced pulp and paper manufacturer manufacturing facility, producing many types of quality writing and printing papers. This 15-ton biomass steam boiler will be used in the production process of concentration, bleaching and drying in the papermaking process.

The features of 15 ton szl series biomass steam boilers

Rated capacity: 15 ton/hr

Working pressure: 1.25 Mpa

Structure: horizontal, Water Tube

Output: Steam

Fuel: biomass pellets

Weight: 21TON

Thermal efficiency: 88%

Operation style: Automatic Chain Grate Stoker Biomass Boiler

Our professional after-sales service personnel will work with the furnace worker every three months to maintain the products purchased by customers, guide customers to use them, and solve your problems. Every six months, they make a return visit to understand the operation of the equipment and eliminate abnormal conditions in the bud.