Introduction

In the dynamic landscape of industrial production, steam boilers play a crucial role in meeting energy demands efficiently while adhering to stringent environmental regulations. As industries across Indonesia strive to enhance productivity and sustainability, the need for high-performance steam boilers has become more pronounced. The Indonesian market is characterized by fierce competition among various suppliers, making it essential for businesses to choose the right Indonesia boiler manufacturer that can provide reliable, efficient, and environmentally friendly solutions.

The Current Landscape of Indonesia Boiler Manufacturers

The current state of the Indonesia boiler manufacturer landscape reveals a myriad of options, but not all manufacturers offer the same level of quality or service. Businesses must navigate this competitive market carefully to select a manufacturer that aligns with their operational needs and sustainability goals. A reliable Indonesia boiler manufacturer not only ensures the provision of high-quality equipment but also offers comprehensive support throughout the lifecycle of the product.

ZOZEN: A Leading Indonesia Boiler Manufacturer

After entering the Indonesian market, ZOZEN stood out in this highly competitive field and became a top Indonesian boiler manufacturer.. With a proven track record of delivering high-performance and reliable products, ZOZEN has established itself as a leader in the industry. The company’s commitment to excellence extends beyond the manufacturing of boilers; ZOZEN is dedicated to providing all-encompassing customer service that includes pre-sales consultation, installation, commissioning, and after-sales maintenance.

ZOZEN’s comprehensive approach to customer service ensures that clients receive the support they need at every stage of their boiler’s lifecycle. This level of service is critical in ensuring the optimal operation and longevity of industrial boilers, further solidifying ZOZEN’s reputation as a preferred Indonesia boiler manufacturer.

ZOZEN’s Industrial Boiler Offerings

ZOZEN offers a wide range of industrial boilers categorized by fuel type, including oil, gas, biomass, and coal.

The oil and gas-fired boilers include the WNS series, SZS series, YQW series, and YQL series:

WNS Series Steam Boilers: These are three-pass wet-back oil/gas boilers with a thermal capacity of 1-20 t/h and a working pressure of 0.7-2 MPa. Equipped with advanced control systems, these boilers can operate unattended, providing efficiency and reliability.

SZS Series Steam Boilers: These are double-drum, horizontal, D-type boilers with a thermal capacity ranging from 2-110 t/h and a working pressure of 1.25-5.3 MPa. The membrane water-cooling wall and large furnace design enhance thermal efficiency.

YQW Series Thermal Oil Boilers: Horizontal oil/gas thermal oil boilers, with thermal capacities from 1400 to 14,000 kW and a working pressure of 0.8-1.0 MPa, these boilers utilize advanced control systems for precise temperature and pressure management.

YQL Series Thermal Oil Boilers: Vertical oil/gas thermal oil boilers that offer a thermal capacity of 7000-29,000 kW and a working pressure of 0.8-1.0 MPa, ensuring efficient operation for diverse industrial applications.

For biomass and coal-fueled boilers, ZOZEN offers the SZL series, DZL series, DHL series, and YLW series:

SZL Series Steam Boilers: Horizontal double-drum chain grate boilers with a thermal capacity of 6-35 t/h and a working pressure of 1-2.5 MPa. Their densely arranged water-cooling wall tube structure provides a large radiation area.

DZL Series Steam Boilers: Horizontal three-pass water-fire tube chain grate boilers with thermal capacities of 2-10 t/h and working pressures of 1-2.5 MPa. Designed for easy installation, they feature lightweight chain grate combustion equipment.

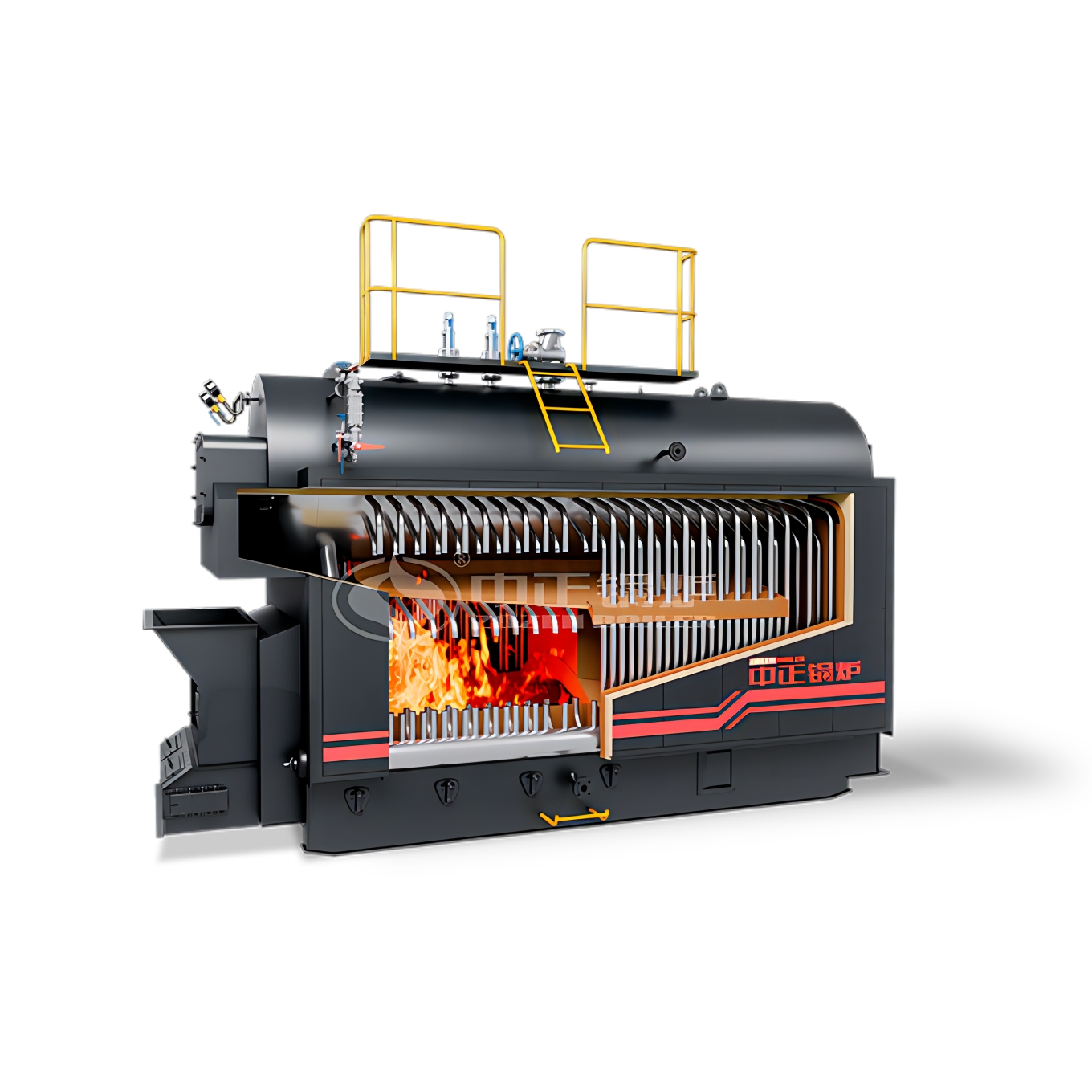

DHL Series Steam Boilers: Corner tube boilers with thermal capacities of 20-75 t/h and working pressures of 1.25-5.4 MPa. Their design includes cross-beam chain grate and membrane water-cooled wall structures to ensure complete combustion of fuel.

YLW Series Thermal Oil Boilers: Horizontal coal/biomass thermal oil boilers offering thermal capacities from 1400-29,000 kW and working pressures of 0.8-1.0 MPa. Featuring advanced control systems, these boilers provide precise oil temperature and pressure control.

Additionally, ZOZEN has developed a proprietary biomass boiler—the DZL series horizontal ash-free biomass steam boiler—with thermal capacities of 15-40 t/h and working pressures of 1.25-2.5 MPa. This innovative design incorporates a blowing device for the convection heating surface, enabling operation without shutdown, tailored to different fuel types.

ZOZEN DZL Series Biomass Fired Boiler

Commitment to Efficiency, Low Emissions, and Intelligent Control

ZOZEN’s products are characterized by high efficiency, low emissions, and intelligent control systems, making them ideal choices for industries aiming to reduce their environmental footprint. The company’s commitment to environmental protection and sustainable development is evident in its innovative boiler designs and advanced technology.

As industries in Indonesia seek reliable partners to meet their energy needs, ZOZEN remains a top choice for businesses looking for a leading Indonesia boiler manufacturer. With a strong focus on quality, performance, and customer satisfaction, ZOZEN continues to set the standard in the industrial boiler market.

Conclusion

The selection of the right Indonesia boiler manufacturer is vital for industrial businesses seeking efficiency, reliability, and sustainability. ZOZEN’s extensive product range and customer-focused approach ensure that clients can confidently meet their energy demands while adhering to environmental standards. By partnering with ZOZEN, businesses can secure the performance and reliability they need in today’s competitive industrial landscape.