Growing Demand for Efficient Industrial Boilers

In recent years, there has been a significant surge in the demand for efficient industrial boilers. This trend is driven by increasing regulatory pressures and environmental requirements that encourage industries to adopt cleaner technologies. Governments around the world are implementing stricter emissions regulations and promoting energy-efficient solutions to combat climate change. As a result, companies are investing in high-efficiency industrial boilers that not only comply with environmental standards but also contribute to cost savings through improved energy utilization.

The emphasis on sustainable practices has made it imperative for industries to upgrade their boiler systems. High-efficiency industrial boilers not only reduce greenhouse gas emissions but also lower operational costs. This growing demand highlights the importance of considering industrial boiler cost when making purchasing decisions, as the initial investment can yield substantial long-term savings.

The Importance of Industrial Boiler Cost

When selecting an industrial boiler, understanding industrial boiler cost is crucial. The price of a boiler can significantly impact the overall budget for a project, and it’s essential to consider both initial costs and long-term operational expenses. Factors influencing industrial boiler cost include:

Type of Boiler: Different boiler designs and configurations come with varying price tags. For instance, steam boilers, hot water boilers, and thermal oil boilers all have different cost structures based on their complexity and efficiency.

Fuel Type: The choice of fuel also plays a significant role in determining industrial boiler cost. Boilers that run on oil and gas may have different upfront costs compared to those using biomass or coal.

Capacity and Pressure: The thermal capacity and working pressure of the boiler will also affect its price. Higher capacity and pressure ratings typically result in higher costs due to the need for more robust materials and design specifications.

Technology and Features: Advanced control systems, automation features, and materials used in construction can increase the price of a boiler. However, investing in technology that enhances efficiency can lead to lower operational costs over time.

ZOZEN’s Industrial Boiler Offerings

ZOZEN provides a wide range of industrial boilers tailored to meet diverse needs. For oil and gas-fired boilers, ZOZEN offers:

WNS Series: These are three-pass wet-back oil/gas steam boilers with a thermal capacity ranging from 1 to 20 t/h and working pressure of 0.7 to 2 MPa. The advanced control system allows for unattended operation, enhancing efficiency.

ZOZEN WNS Series Gas/Oil Fired Industrial Boiler

SZS Series: Designed with a double-drum, horizontal layout, these boilers have a thermal capacity from 2 to 110 t/h and a working pressure of 1.25 to 5.3 MPa. Their membrane water-cooled wall design improves heat transfer efficiency.

YQW Series: These horizontal thermal oil boilers use oil or gas, with thermal capacities from 1400 to 14000 kW and a working pressure of 0.8 to 1.0 MPa.

YQL Series: Vertical thermal oil boilers with a thermal capacity of 7000 to 29000 kW and working pressure of 0.8 to 1.0 MPa.

For biomass and coal-fired boilers, ZOZEN offers:

SZL Series: Horizontal double-drum chain grate water-tube boilers with thermal capacities from 6 to 35 t/h and working pressures of 1 to 2.5 MPa.

DZL Series: Horizontal three-pass fire-tube chain grate boilers with thermal capacities from 2 to 10 t/h and working pressures of 1 to 2.5 MPa.

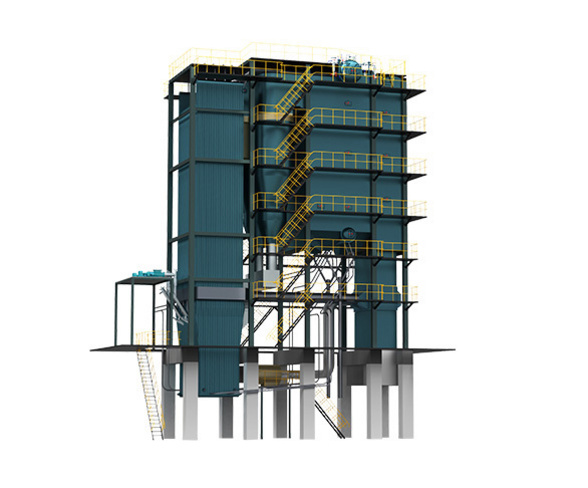

DHL Series: Corner tube boilers with thermal capacities from 20 to 75 t/h and working pressures of 1.25 to 5.4 MPa.

YLW Series: Horizontal coal and biomass thermal oil boilers, with capacities from 1400 to 29000 kW and working pressures of 0.8 to 1.0 MPa.

Additionally, ZOZEN has developed an innovative biomass boiler, the DZL Series Horizontal Ash-Free Biomass Steam Boiler, with thermal capacities of 15 to 40 t/h and working pressures of 1.25 to 2.5 MPa. This boiler features a unique design to facilitate ash removal without shutdown, enhancing operational efficiency.

Competitive Advantages in Industrial Boiler Cost

ZOZEN’s competitive edge in industrial boiler cost comes from various factors, including material selection, advanced technology, and market positioning. The company employs high-quality materials and state-of-the-art manufacturing processes, ensuring durability and efficiency. Furthermore, ZOZEN offers flexible pricing strategies tailored to customer needs, allowing for adjustments based on project specifications and budget constraints.

After-Sales Service: Enhancing Customer Value

ZOZEN’s comprehensive after-sales service system provides customers with reassurance regarding their investment. With a focus on high-quality service, ZOZEN enhances customer satisfaction and helps them recognize the value of their industrial boiler cost. This support system includes regular maintenance, technical assistance, and rapid response to service requests, ensuring optimal performance and longevity of the boilers.

Conclusion

Understanding industrial boiler cost is essential for making informed purchasing decisions in an evolving market driven by efficiency and environmental responsibility. ZOZEN’s wide range of offerings, combined with its competitive pricing strategies and robust after-sales service, positions it as a leader in the industrial boiler sector, providing solutions that meet both current demands and future challenges.