Part 1: Factors Influencing Industrial Boiler Prices

When considering the industrial boiler price, several key factors play a significant role in determining the final cost. Understanding these factors is essential for businesses looking to make informed decisions about their boiler investments.

Boiler Type: Different types of industrial boilers, such as fire-tube, water-tube, or biomass boilers, come with varying price points based on their design complexity and materials used.

Size and Capacity: The physical size and heating capacity of a boiler directly impact industrial boiler price. Larger boilers with higher capacities typically command a higher industrial boiler price due to the increased materials and engineering required.

Fuel Type: The type of fuel a boiler uses—such as natural gas, oil, coal, or biomass—affects both the initial purchase price and ongoing operational costs.

Brand Reputation: Established brands with a history of quality products and reliable performance may charge a premium for their boilers compared to lesser-known brands.

Installation and Maintenance Costs: The complexity of installing a boiler, including any necessary modifications to existing systems, as well as ongoing maintenance requirements, can influence the total cost of ownership.

Market Demand: Fluctuations in market demand for industrial boilers can affect industrial boiler prices. During high demand periods, prices may rise due to supply constraints or increased production costs.

Technological Advancements: Boilers incorporating advanced technologies, such as smart controls, remote monitoring capabilities, or energy-saving features, may come at a higher industrial boiler price point but offer enhanced efficiency and convenience.

Part 2: ZOZEN’s Approach to Industrial Boiler Price

Within the competitive market of industrial boilers, ZOZEN distinguishes itself with a customer-centric pricing strategy. ZOZEN sets its industrial boiler prices based on the unique needs of its clientele, ensuring a harmonious blend of top-notch quality and affordability. By prioritizing high thermal efficiency and low operational costs, ZOZEN’s boilers not only save businesses money but also enhance overall cost-effectiveness. This emphasis on delivering value underscores ZOZEN’s commitment to offering a superior product at a reasonable price point.

Part 3: Exploring ZOZEN’s Steam Boiler Portfolio

In terms of ZOZEN’s steam boiler offerings, they cater to various fuel types, with distinctions between oil and gas-fueled boilers and those using biomass or coal as fuel sources.

The oil and gas-fueled steam boilers from ZOZEN include the following series:

WNS Series: These boilers are three-pass wet-back oil/gas-fired boilers with a thermal capacity ranging from 1 to 20 t/h and a working pressure of 0.7-2 MPa. They feature advanced control systems for unmanned operation and boast a thermal efficiency of at least 98%.

ZOZEN SZS Series Gas/Oil Industrial Boiler

SZS Series: These boilers are dual-drum, horizontal, D-type layout structures with a thermal capacity ranging from 2 to 110 t/h and a working pressure of 1.25-5.3 MPa. The use of membrane water-cooled walls and a large furnace design enhances heat transfer efficiency, achieving a thermal efficiency of over 98%.

For biomass and coal-fueled steam boilers, ZOZEN offers the following series:

SZL Series: These boilers are horizontal dual-drum chain grate boiler with a thermal capacity of 6-35 t/h and a working pressure of 1-2.5 MPa. Their furnace features a closely arranged water-cooled wall tube structure with a large radiation area, ensuring a thermal efficiency greater than 81%.

DZL Series: These boilers are horizontal three-pass water-fire tube chain grate boilers with a thermal capacity ranging from 2 to 10 t/h and a working pressure of 1-2.5 MPa. They utilize a lightweight chain grate combustion device and are factory-assembled for quick installation, achieving a thermal efficiency exceeding 80%.

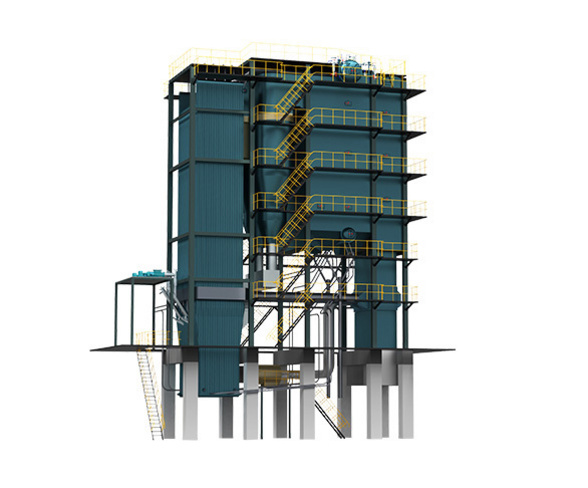

DHL Series: These boilers are angle tube boilers with a thermal capacity of 20-75 t/h and a working pressure of 1.25-5.4 MPa. They employ a beam-type chain grate and membrane water-cooled wall structure to ensure thorough fuel combustion, with a thermal efficiency of at least 82%.

In addition to these, ZOZEN has developed a biomass steam boiler with independent intellectual property rights: the DZL Series Horizontal Non-Coking Biomass Steam Boiler. This boiler has a thermal capacity of 15-40 t/h and a working pressure of 1.25-2.5 MPa. It features ash blowing devices at the rear convection heating surface and ash blowing holes at the top of the furnace, allowing for ash cleaning without shutdown. The thermal efficiency of this boiler is no less than 87.5%.

Part 4: ZOZEN’s Service Commitment

Beyond product excellence, ZOZEN distinguishes itself with a robust after-sales service system. Rapid response times and expert support underscore ZOZEN’s dedication to customer satisfaction, ensuring a seamless experience for clients throughout their boiler lifecycle.

Conclusion

ZOZEN’s tailored approach to industrial boiler price, diverse steam boiler portfolio, and steadfast commitment to customer service position it as a leading player in the industrial boiler market. By balancing quality, affordability, and service excellence, ZOZEN remains a trusted partner for businesses seeking reliable and cost-effective boiler solutions.