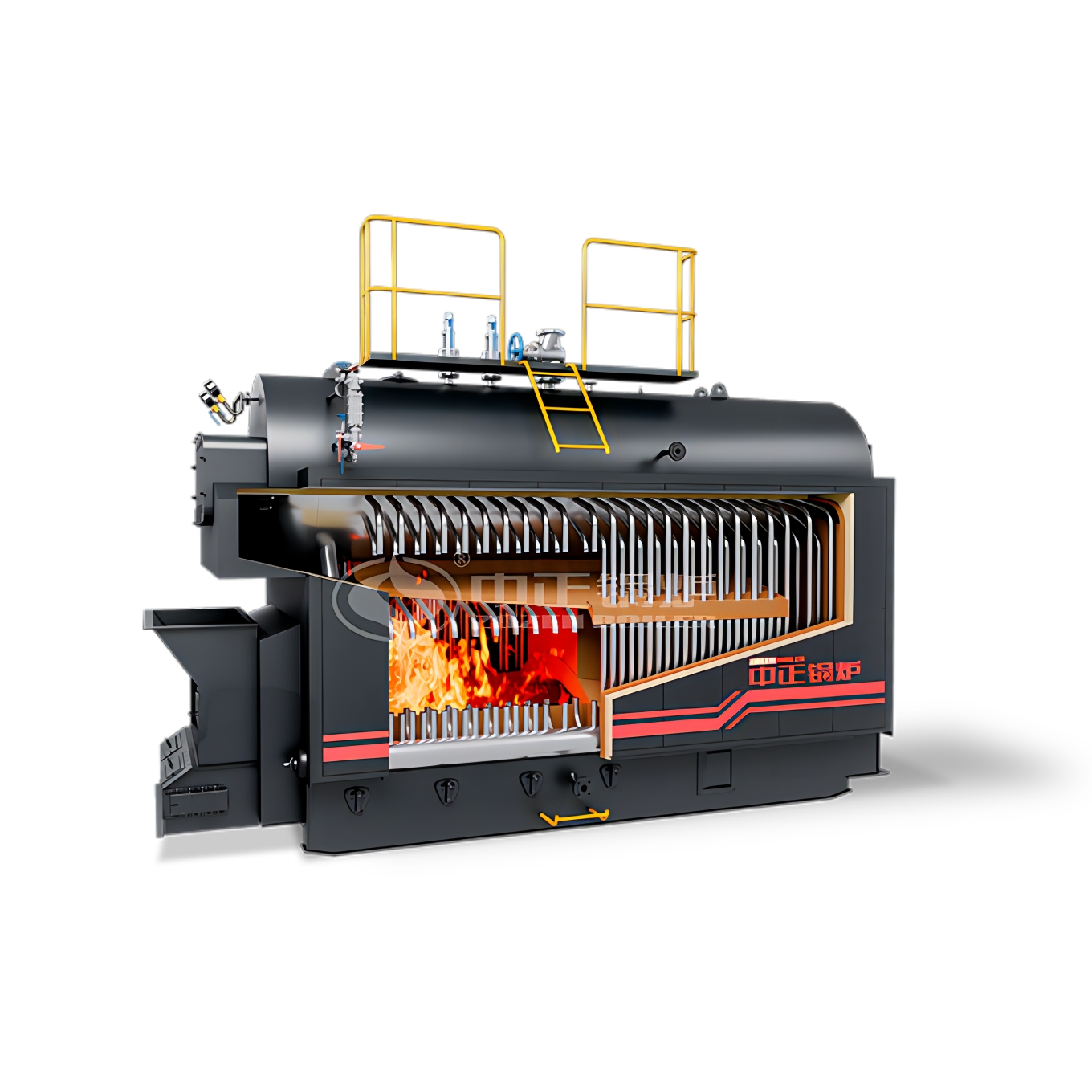

WNS series industrial boiler adopt horizontal three return wet back corrugated furnace structure. It is mainly composed of pot shell, furnace bladder, smoke chamber and smoke pipe. Wet-back, corrugated furnace structure, symmetrical arrangement of heating surface. Effectively reduce the boiler thermal stress, improve the safety of boiler use and life. The heat transfer effect of smoke pipe is improved by using heat transfer thread pipe.

This series of industrial boilers also have good thermal expansion and cold contraction performance, which can prevent the heating surface from deformation. The boiler adopts the combustion chamber with low position arrangement, which makes the safe range of boiler water level larger, the boiler steam space larger, and the steam quality is well guaranteed. The fin type energy saver with steel tube is arranged at the end, which has high heat transfer efficiency. The smoke temperature at the back of the energy saver is no more than 150℃, thus reducing fuel consumption.

WNS series industrial boiler for sale adopts high quality aluminum silicate to encrypt heat preservation and reduce heat dissipation loss. The heating surface of the boiler is sufficiently arranged, the boiler starts quickly, and the loading time is short. Maintain access door hole, convenient maintenance. Adopt the whole quick installation type structure, the boiler structure is compact, occupies a small area, installs quickly. The combustion of the boiler is realized by using the main burner, which can save fuel and reduce pollution, noise and exhaust emissions. The gas fired boiler adopts advanced mechatronics automatic control technology. Remote human-computer interaction and data sharing can be realized through mobile Internet.

The difference between coal-fired boilers and gas-fired boilers

- In terms of energy saving and environmental protection: coal is mainly composed of elements such as C, H, O, N, S and ash and moisture, coal combustion heat, the generation of SO2, SO3, N Ox ash and moisture, flue gas emissions into the atmosphere, pollution of the environment, causing harm to humans. The main component of natural gas is CH4, and after combustion, it mainly produces CO2 and H2O, and the emissions of SO2, SO3, and N Ox are much less than those of coal-fired boilers.

- In terms of operation: gas-fired boilers are highly adaptable to the heating load and flexible in system adjustment; the system starts and stops quickly, and the degree of self-control is high. With less impurities in the gas, the boiler does not suffer from corrosion and slagging of the heating surface, and the boiler has a long continuous operating cycle; coal-fired boilers are safe to burn, and the chamber is less likely to explode. While gas-fired boilers within the limits of explosive concentration, the explosion will occur when encountering an open flame, which is more dangerous.

- In terms of cost savings: gas boilers use piped gas as fuel, no fuel reserves, saving space and labor; no fuel processing and preparation equipment before supplying fuel; gas boilers do not need to configure soot blowers, dust collectors, slagging equipment, less ancillary equipment, electricity consumption is lower than coal-fired boilers; gas boilers are more compact than coal-fired boilers of the same capacity, small size, light weight, significantly reduced investment in equipment; WNS series gas boilers save coal-fired boilers used to dust, slagging and other dust-proof auxiliary water.

The WNS series industrial boiler can use integrated low nitrogen (NOx) control technology including flue gas recirlation (FGR) to achieve high combustion efficiency, low pollutant emission, and ensure NOx emission meets the environmental protection emission requirements of the boiler. Zozen Boilers products specializing in the production of high quality boiler, welcome everyone to come to consult procurement, we will serve you wholeheartedly.