Case Introduction

Shanxi Shuangyan Pharmaceutical Co., Ltd. was established in 2004 and is a comprehensive pharmaceutical enterprise integrating drug research and development, production, and sales. The company is dedicated to the R&D and production of high-quality pharmaceuticals and has built a solid reputation and influence within the industry, becoming an important player in Shanxi’s pharmaceutical sector.

In the pharmaceutical industry, boilers are indispensable heat supply equipment in the production process. They are not only used for key processes such as heating, evaporation, and distillation but also provide essential steam power for the entire plant. However, traditional boiler technologies often come with high energy consumption and environmental pollution issues, posing challenges to the sustainable development of enterprises.

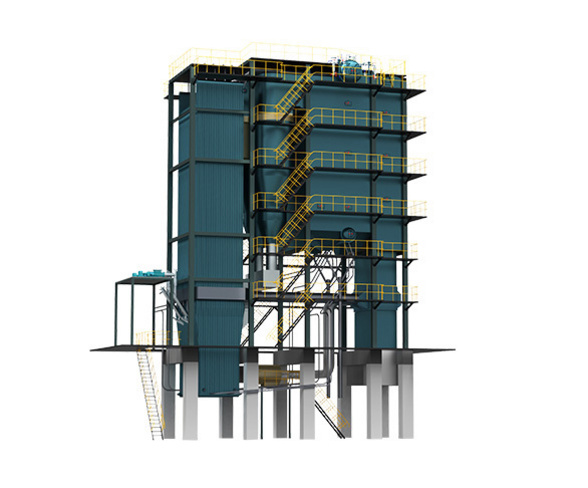

To address this, ZOZEN Boiler has provided Shuangyan Pharmaceutical with a competitive boiler solution that meets the production needs of the pharmaceutical industry: the DHX series coal-fired circulating fluidized bed steam boiler. This boiler combines advanced technology and environmental protection concepts, helping the company pursue efficiency while also fulfilling its social responsibility.

Compared to traditional pulverized coal boilers, the DHX series achieves low-temperature combustion, effectively reducing nitrogen oxide emissions to around 100 mg/Nm³. This ultra-low emission characteristic not only complies with national environmental protection standards but also provides strong support for Shuangyan Pharmaceutical’s green production. Additionally, the DHX series directly achieves high-efficiency desulfurization during combustion, with a desulfurization efficiency of over 90%. This technology not only reduces environmental pollution and lowers operating costs but also enhances Shuangyan Pharmaceutical’s competitiveness in the industry.

Through its collaboration with ZOZEN Boiler, Shuangyan Pharmaceutical has not only optimized its production processes but also improved energy utilization efficiency, achieving a win-win situation for economic benefits and environmental protection, demonstrating the company’s firm commitment to green sustainable development in modern pharmaceuticals.

Customer Feedback

We are extremely satisfied with our collaboration with ZOZEN Boiler, especially the performance of the DHX series coal-fired circulating fluidized bed steam boiler, which has exceeded our expectations. This boiler has not only significantly enhanced our production efficiency but also effectively reduced nitrogen oxide emissions, ensuring our commitment to environmental protection. We particularly appreciate its low-temperature combustion technology and high-efficiency desulfurization capabilities, which have lowered our operating costs and made our production processes more green and sustainable. Through this partnership, we are more confident in promoting the green development of our enterprise in the future.— Shanxi Shuangyan Pharmaceutical Co., Ltd.