Case Introduction

Shanxi Shuangyan Pharmaceutical Co., Ltd. was established in 2004 with a registered capital of 100 million yuan. It is a comprehensive pharmaceutical enterprise that integrates drug research and development, production, and sales. The company has been deeply involved in the pharmaceutical industry for many years and, with its strong R&D and production capabilities, has become a leader in the industry. As the scale of pharmaceutical production continues to expand, ensuring efficient heat energy supply in the production process has become a key issue that Shuangyan Pharmaceutical needs to address.

In the pharmaceutical production process, boilers play an irreplaceable role as crucial heat energy supply equipment. They are used not only for heating, evaporation, and distillation in multiple process stages but also provide the necessary steam power for the entire factory. However, traditional boilers often have issues such as high energy consumption, low efficiency, and significant environmental pollution. The challenge for the pharmaceutical industry is to meet production needs while reducing energy consumption and achieving environmentally friendly emissions.

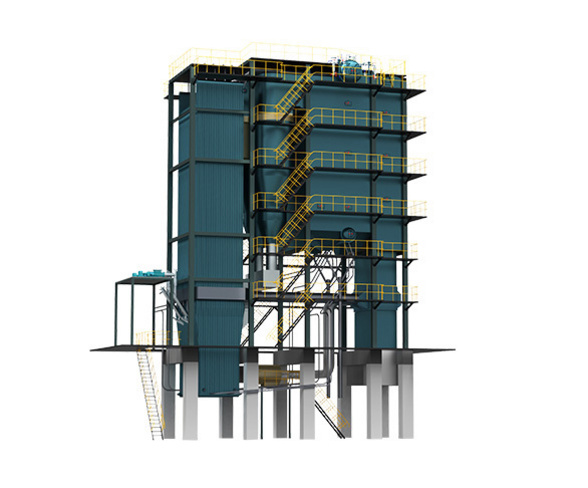

To address this issue, Shuangyan Pharmaceutical chose the DHX series coal-fired circulating fluidized bed steam boiler from ZOZEN Boiler. This series of boilers has many technological innovations, and compared to traditional pulverized coal boilers, the DHX series offers significant advantages, making it the ideal heat energy solution for Shuangyan Pharmaceutical’s production process.

Firstly, the low-temperature combustion technology of the DHX series boilers effectively reduces nitrogen oxide emissions, with emission concentrations controlled around 100 mg/Nm³, which is much lower than the emission levels of traditional boilers. This complies with the strict environmental standards set by the government and ensures that Shuangyan Pharmaceutical’s production activities take place within an environmentally friendly framework, contributing to the company’s sustainable development.

Secondly, the high-efficiency desulfurization technology allows the boiler to directly achieve efficient desulfurization during the combustion process, with a desulfurization efficiency of over 90%, significantly reducing sulfur dioxide emissions and further lowering environmental pollution. Moreover, the application of desulfurization technology reduces the environmental remediation costs that the company might incur due to pollutant emissions.

From an economic perspective, the DHX series boilers not only offer excellent environmental performance but also lower fuel consumption and operational costs through efficient combustion and heat recovery technology. Their high efficiency not only enhances production efficiency but also brings significant economic benefits to Shuangyan Pharmaceutical’s long-term development.

The boiler solution provided by ZOZEN Boiler for Shuangyan Pharmaceutical meets the pharmaceutical industry’s need for high performance, low emissions, and cost-effectiveness. Through this technological innovation, Shuangyan Pharmaceutical has ensured production efficiency while enhancing its environmental competitiveness, demonstrating its social responsibility and commitment to green development as an industry leader.

Customer Feedback

Our collaboration with ZOZEN Boiler has been very smooth. The introduction of the DHX series coal-fired circulating fluidized bed steam boiler has not only greatly improved our production efficiency but also significantly reduced energy consumption and emissions. The solution provided by ZOZEN Boiler has enhanced our production benefits and saved us considerable operating costs. We are very satisfied with ZOZEN Boiler’s professional service and technical strength, and we look forward to deepening our cooperation in the future to jointly promote the sustainable development of the enterprise. — Shanxi Shuangyan Pharmaceutical Co., Ltd.